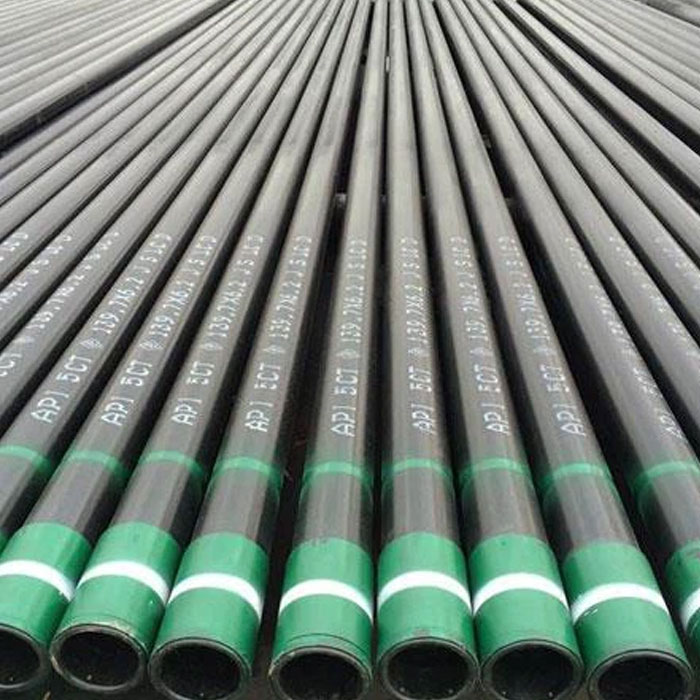

Products Descriptions

● Product name: Hot Rolled Fluid Piping

● Standards: AISI, ASTM, BS, DIN, GB, JIS

● Place of origin: Tianjin, China (Mainland)

● Brand name: Runfei

● Payment terms: L/C, T/T (30% deposit)

● Certifications: ISO 9001, SGS, RoHS Directive-compliant

● Packing details: Standard seaworthy packing, horizontal type and vertical type are all available

Our Advantages

● We can provide factory price with trading company services

● We control production quality very strictly to keep none compensation

● We guarantee 24 hours response and 48 hours solution providing service

● We accept small order quantity before formal cooperation

● We offer good quality with reasonable price, faster delivery with better payment terms

● We have professional teams and the factory

● It’s very important for a company to be honest in the process of trading and so do we

Main production process of hot-rolled seamless steel pipe (main inspection process):

Tube blank preparation and inspection → Tube heating → Perforation → Rolling tube → Steel tube reheating→ Fixed (reduced) diameter→ heat treatment →finished tube straightening→ finishing→ inspection (non-destructive, physicochemical, Taiwan inspection)→Warehousing.

Cold rolling (drawing) seamless steel pipe main production process: Blank preparation → pickling lubrication → cold rolling (pull) → heat treatment → straightening → finishing → inspection.

The production process of general seamless steel pipe can be divided into cold drawing and hot rolling. The production process of seamless steel pipe is generally more complicated than spiral submerged arc welding pipe. The pipe blank must first be rolled in three rolls. In the diameter test, if the surface does not respond to the crack, the round tube is cut by a cutter and cut into a blank having a length of about one meter. Then enter the annealing process, the acidification should be acid-washed with acid liquid.

When pickling, pay attention to whether there is a large amount of foaming on the surface. If there is a large amount of foaming, the quality of the steel pipe will not reach the corresponding standard. The appearance of cold-rolled pipe is shorter than that of hot-rolled pipe. The wall thickness of cold-rolled pipe is generally smaller than that of hot-rolled pipe, but the surface looks brighter than thick-walled seamless steel pipe, the surface is not too rough, and the diameter is not too More burrs.

The delivery status of the hot-rolled seamless steel pipe is generally delivered after the heat treatment in the hot rolled state. After the quality inspection, it is subject to strict manual selection by the staff. After the quality inspection, the surface is oiled, followed by multiple cold drawing experiments. After the hot rolling treatment, the perforation experiment is carried out. If it is too large, it will be straightened and corrected. After straightening, the conveyor is sent to the flaw detector for flaw detection experiments. Finally, the label is placed, the specifications are arranged, and then placed in the warehouse.

Round tube billet → heating → perforation → three-roll cross-rolling, continuous rolling or extrusion → stripping → sizing (or reducing diameter) → cooling → straightening → hydrostatic test (or flaw detection) → marking → storage. The seamless steel pipe is formed by perforating a steel ingot or a solid tube blank, and then hot rolled, cold rolled or cold drawn. The specifications of the seamless steel pipe are expressed by the outer diameter * wall thickness in millimeters. The outer diameter of hot-rolled seamless pipe is generally larger than 32mm, the wall thickness is 2.5-200mm, the outer diameter of cold-rolled seamless steel pipe can reach 6mm, the wall thickness can be 0.25mm, the outer diameter of thin-walled pipe can reach 5mm, the wall thickness is less than 0.25mm, cold Rolling is more accurate than hot rolling.

Generally, the seamless steel pipe is formed by hot-rolled or cold-rolled low-alloy structural steels such as 10, 20, 30, 35, 45, etc., such as 16Mn and 5MnV, or 40Cr, 30CrMnSi, 45Mn2, 40MnB, and the like. Seamless pipes made of low carbon steel such as 10 and 20 are mainly used for fluid conveying pipes. 45, 40Cr and other medium carbon steel seamless pipes are used to make mechanical parts, such as the force parts of automobiles and tractors. Generally, seamless steel pipes are required to ensure strength and flattening test. The hot rolled steel pipe is delivered in a hot rolled state or a heat treated state; the cold rolling is delivered in a heat treated state by heat.Hot rolling, as the name suggests, has a high temperature of the rolled piece, so the deformation resistance is small and a large amount of deformation can be achieved.

Taking the rolling of the steel sheet as an example, the thickness of the continuous casting blank is generally about 230 mm, and after rough rolling and finish rolling, the final thickness is 1 to 20 mm. At the same time, due to the small width-to-thickness ratio of the steel plate, the dimensional accuracy requirement is relatively low, and the shape problem is not easy to occur, and the convexity is mainly controlled.

Hot Tags: hot rolled fluid piping, China, suppliers, manufacturers, factory, price, quotation, high quality, Hot Rolled Fluid Piping, Hot Rolled Cylinder Tube, Hot Roller Automobile Half Axle Sleeve, ALUZINC STEEL SHEET, Hot Rolled Hydraulic Pillar Pipe, Hot Rolled Ejector Pins Steel.