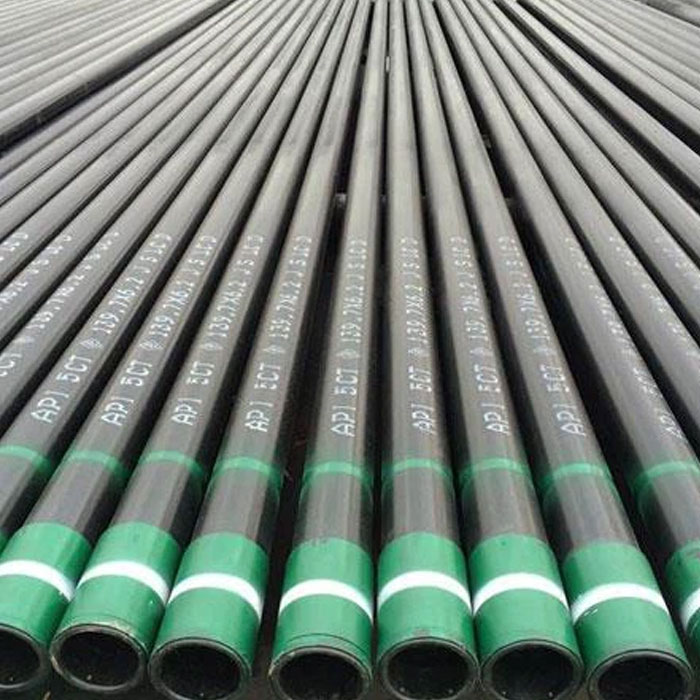

Products Descriptions

● Product name: External Thickness Oil Tubing

● Standards: AISI, ASTM, BS, DIN, GB, JIS

● Place of origin: Tianjin, China (Mainland)

● Brand name: Runfei

● Payment terms: L/C, T/T (30% deposit)

● Certifications: ISO 9001, SGS, RoHS Directive-compliant

● Packing details: Standard seaworthy packing, horizontal type and vertical type are all available

Our Advantages

● We can provide factory price with trading company services

● We control production quality very strictly to keep none compensation

● We guarantee 24 hours response and 48 hours solution providing service

● We accept small order quantity before formal cooperation

● We offer good quality with reasonable price, faster delivery with better payment terms

● We have professional teams and the factory

● It’s very important for a company to be honest in the process of trading and so do we

The use of tubing permits better well control because circulating fluids can kill the well; thus, workovers are simplified and their results enhanced. Flow efficiency typically is improved with the use of tubing. Furthermore, tubing is required for most artificial lift installations. Tubing with the use of a packer allows isolation of the casing from well fluids and deters corrosion damage of the casing. Multicompletions require tubing to permit individual zone production and operation. Governmental rules and regulations often require tubing in every well. Permission may be obtained for omission of tubing in special cases (tubingless completions). These special completions typically are flowing wells with relatively small casing. Tubing strings are generally in outside diameter (OD) sizes of 2 3/8 to 4 1/2 in. but may be as large as 20 in. or as small as 1.050 in.

The proper selection, design, and installation of tubing string are critical parts of any well completion. Tubing strings must be sized correctly to enable the fluids to flow efficiently or to permit installation of effective artificial lift equipment. A tubing string that is too small causes large friction losses and limits production. It also may severely restrict the type and size of artificial lift equipment. A tubing string that is too large may cause heading and unstable flow, which results in loading up of the well and can complicate workovers. The planned tubing must easily fit inside the installed casing. When selecting the material, the following must be considered:

● Environmental conditions

● Projected corrosivity of the well fluids

● Minimum and maximum pressures and temperature

● Safety aspects

● Cost-effectiveness

The tubing must be designed to meet all stresses and conditions that occur during routine operation of the well and should have an adequate margin for unusual load conditions. It must withstand the stresses caused by tension, burst, and collapse, and it must resist the corrosive action of well fluids throughout the well life. In addition, the tubing must be handled and installed so that the tubing produces the well without failure or without causing undue operating problems.

Hot Tags: external thickness oil tubing, China, suppliers, manufacturers, factory, price, quotation, high quality, Hot Rolled Hydraulic Pillar Pipe, Hot Rolled Structural Pipe, Gi Corrugated Sheets, Plain End Sleeve Oil Tubing, Hot Roller Automobile Half Axle Sleeve, Hot Rolled Ejector Pins Steel.