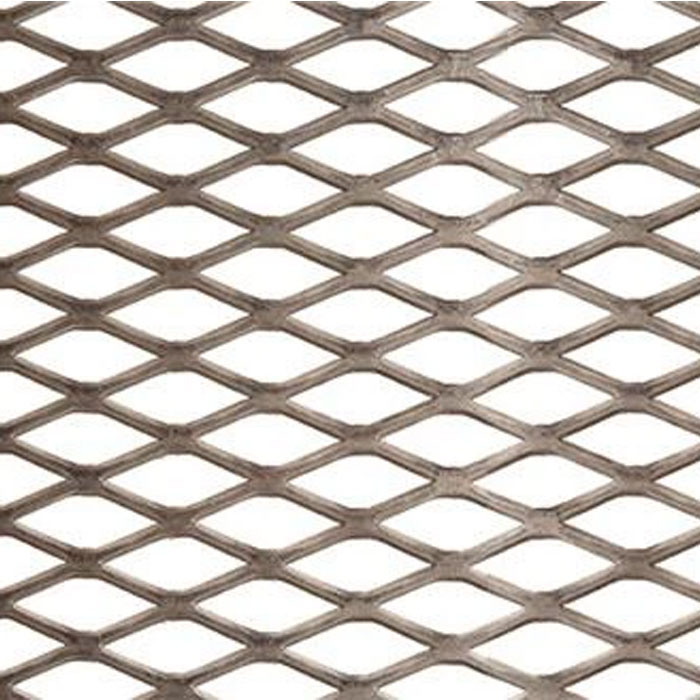

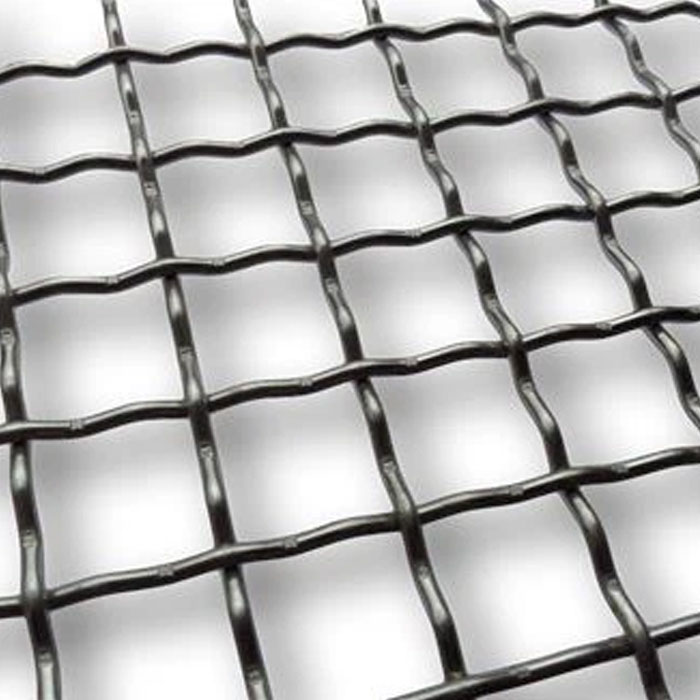

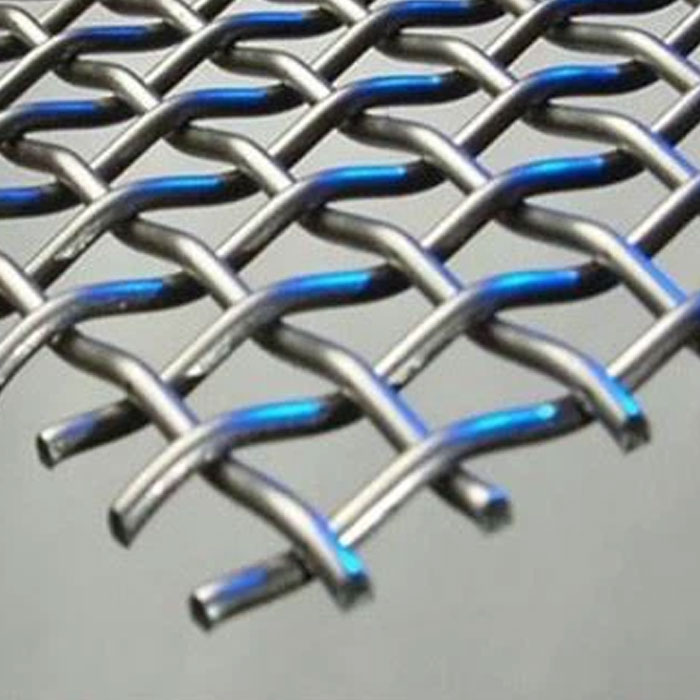

Woven wire mesh is woven to size in the same way cloth is woven on a loom. The mesh can consist of various crimping patterns for the interlocking segments. This interlocking method, which entails the precise arrangement of the wires over and under one another prior to crimping them into place, creates a product that’s strong and reliable. The high-precision manufacturing process makes woven wire cloth more labor-intensive to produce therefore it is typically the more expensive than welded wire mesh.The most common materials used to create woven wire mesh are carbon steel, galvanized steel and stainless steel, and aluminum.

Woven wire mesh materials:

● Carbon steel: Low, High, Oil Tempered

● Stainless Steel: Non-Magnetic Types 304, 304L, 309, 310, 316, 316L, 317, 321, 330, 347; Magnetic Types 410, 430

● Copper and Copper Alloys: Copper, Brass, Bronze, Phosphor Bronze

● Galvanized steel

● Aluminum and Aluminum alloy: 1350-H19

Stainless wire mesh is especially useful because it is extremely chemical resistant, works with hot or cold liquids, and is easily cleaned. Aluminum mesh is lightweight, strong, has a high electrical conductivity, and a low melting point. Aluminum mesh also significantly resists atmospheric corrosion. Carbon steel and galvanized wire mesh are strong, economical, and readily available. Other exotic materials such as copper and nickel can also be woven into wire mesh.

Features of woven wire mesh:

● Solid construction

● Extremely versatile

● Easy to install

● Can have low resistance to wind loads

● Easily cut to fit

● Available in many materials

Woven wire mesh can be used for a variety of applications. Some of application include:

● Sifting and sizing

● Architectural applications when aesthetics are important

● Infill panels that can be used for pedestrian partitions

● Filtration and separation

● Glare control

● RFI and EMI shielding

● Ventilation fan screens

● Handrails and safety guards

● Pest control and livestock cages

● Process screens and centrifuge screens

● Air and water filters

● Dewatering, solids/liquid control

● Waste treatment

● Filters and strainers for air, oil, fuel and hydraulic systems

● Fuel cells and mud screens

● Separator screens and cathode screens

● Catalyst support grids made from bar grating with wire mesh overlay

Our advantages:

● We can provide factory price with trading company services

● We control production quality very strictly to keep none compensation

● We guarantee 24 hours response and 48 hours solution providing service

● We accept small order quantity before formal cooperation

● We offer good quality with reasonable price, faster delivery with better payment terms

● We have professional teams and the factory

● It’s very important for a company to be honest in the process of trading and so do we

FAQ

Q1. What kind of terms of payment?

A:T/T, L/C are available.

Q2. What grads of the product can you offer?

A:These products can be customized according to your requirement.

Q3. Is free sample available?

A:Yes, free sample is available

If you are interested in our products please contact me. My WhatsApp is +8617694942340, or you can fill in the feedback as below, I will contact you as soon as possible.

Hot Tags: woven wire mesh, China, suppliers, manufacturers, factory, price, quotation, high quality, Barbed Wire Fence, Anti climbing Fence, Stainless Steel Screen, Standard Expanded Metal, Concertina Wire Fence, Concertina Coil Fence.