Products Descriptions

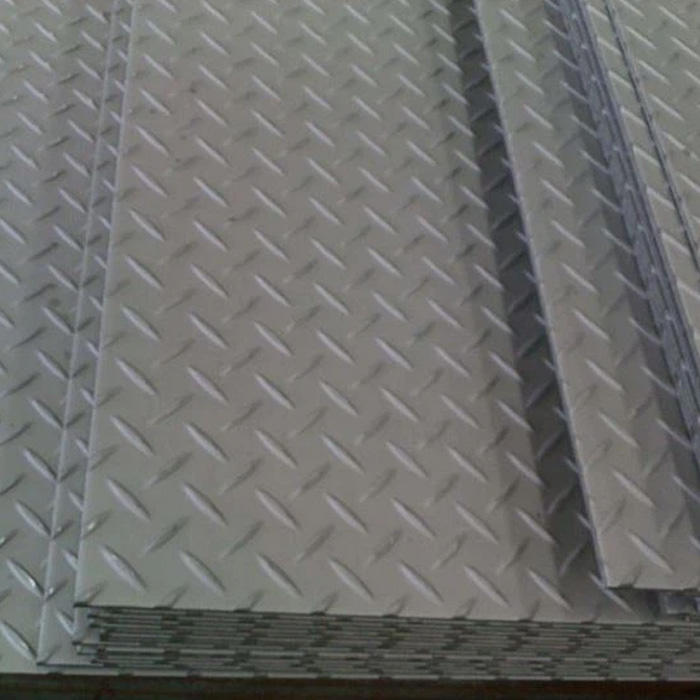

● Product name: Galvanized Steel Embossing Sheet

● Standards: AISI, ASTM, BS, DIN, GB, JIS

● Place of origin: Tianjin, China (Mainland)

● Brand name: Runfei

● Payment terms: L/C, T/T (30% deposit)

● Certifications: ISO 9001, SGS, RoHS Directive-compliant

● Packing details: Standard seaworthy packing, horizontal type and vertical type are all available

Our Advantages

● We can provide factory price with trading company services

● We control production quality very strictly to keep none compensation

● We guarantee 24 hours response and 48 hours solution providing service

● We accept small order quantity before formal cooperation

● We offer good quality with reasonable price, faster delivery with better payment terms

● We have professional teams and the factory

● It’s very important for a company to be honest in the process of trading and so do we

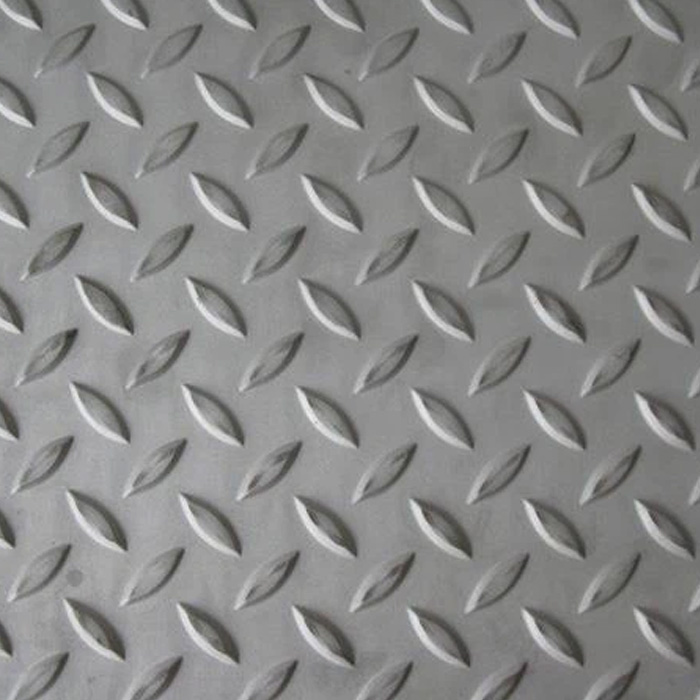

Embossing is a metal stamping process for producing raised or sunken designs or reliefs by passing metal sheet or strip between rolls of a desired pattern. The process enables repeated production without variation and does not change the metal’s wall thicknesses.

Our Steel’s embossed steel service capabilities include slitting, shearing, blanking, degreasing and brushing, stretcher leveling and metallurgical support.

Embossed steel is ideal for customers looking to add aesthetic touches or functional improvements to a product. Embossing can help disperse liquid more effectively, reduce friction and static, bolster metal panel stiffness and rigidity, increase metal surface area for acoustic or heat transfer and improve traction. Applications that use embossed steel include appliance panels, building products, elevator panels, garage door panels, automotive trim and metal office furniture.

Metal sheet is drawn through the male and female roller dies producing a pattern or design on the metal sheet. Depending on the roller dies used, different patterns can be produced on the metal sheet.

Characteristics of the metal embossing process include:

● Its ability to form ductile metals,

● Its use in medium to high production runs,

● The ability to maintain the same metal thickness before and after embossing,

● The ability to produce unlimited patterns, depending on the roll dies, and

● The ability to reproduce product with no variation.

Located within the embossing stand itself are two engraved and mated hardened steel rolls, geared together to maintain top-to-bottom pattern registration. The width and diameter of these rolls depends on the strip width, material thickness, pattern depth, and material tensile strength and hardness.

In most machines, the upper roll blocks are stationary, while the bottom roll blocks are movable. The pressure with which the bottom roll is raised is referred to as the tonnage capacity. This figure also depends on the aforementioned parameters.

Embossing machines are generally sized to give 2″ of strip clearance on each side of an engraved embossing roll. Many embossing machines are custom-manufactured, so there are no industry-standard widths. It is not uncommon to find embossing machines in operation producing patterns less than 6′ wide all the way up to machines producing patterns 70″+ wide.

The illustration that follows provides a two-dimensional look at a typical embossing line setup with an embossing roller in the middle. The illustration shows the metal sheet entering the roller, and then the embossed sheet leaving toward the drawing rollers.

Hot Tags: galvanized steel embossing sheet, China, suppliers, manufacturers, factory, price, quotation, high quality, Galvanized Steel Embossing Sheet, GALVALUME STEEL SHEET, , SGLCC, , High Strength Galvalume Steel Coils.