about runfei

Runfei Steel Group was established in 1998, start with import business, import steel from Ukraine and Russia.

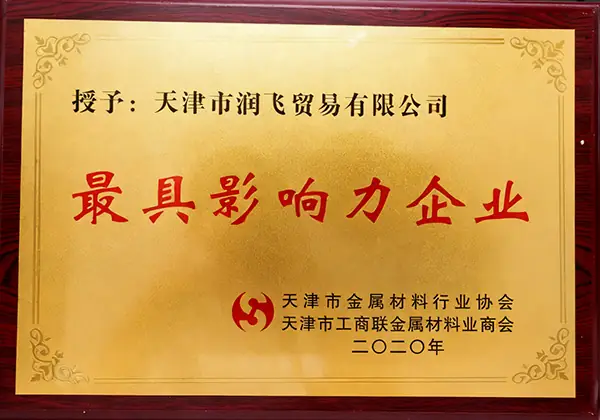

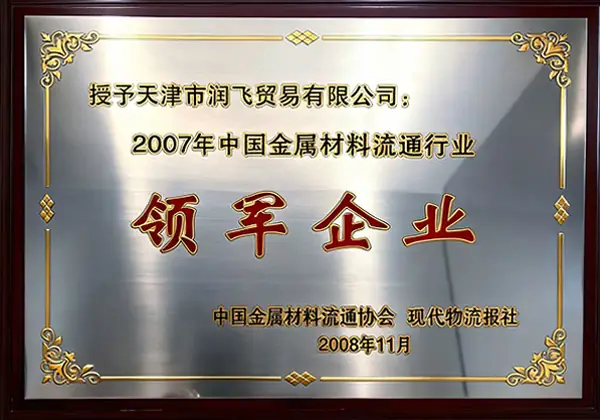

It is a large-scale steel processing and distribution trading company that provides integrated procurement, sales, and distribution services.

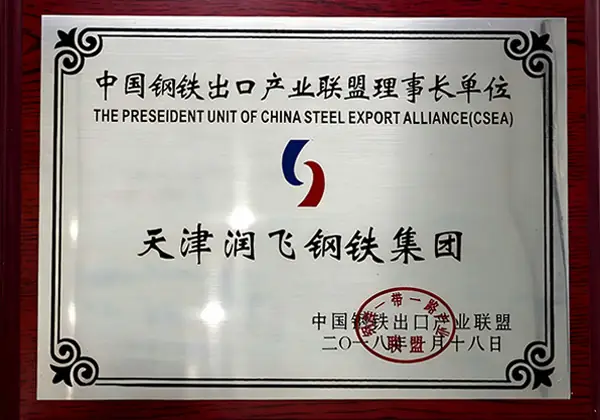

It started to engage in steel export trade in 2006.

The group has a factory covering an area of 170 acres in Tianjin Hangu Industrial Park. Its indoor steel storage capacity reaches 30,000 tons and its comprehensive processing capacity reaches 300,000 tons.