Wear-resistant steel is widely used in machinery manufacturing, mainly for the selection of mechanical component materials, steel balls of ball mills, lining plates, bucket teeth and buckets of excavators, rolling mortar walls, tooth plates and hammer heads of various crushers , Track pads for tractors and tanks, strike plates for fan mills, railway frogs, mid-slot plates, groove tops, ring chains for scraper conveyors in coal mines, blades and shovel teeth for bulldozers, large electric wheeled vehicles Bucket liners, roller cone bits for oil and open-air iron mine perforation, etc. The following small series introduces the types of wear-resistant steel and how to use them.

Types of wear-resistant steel

1. High manganese steel

The cast structure of high-manganese steel is usually composed of austenite, carbide and pearlite, and sometimes contains a small amount of phosphorus eutectic. When the amount of carbide is large, it often appears in a network on the grain boundary. Therefore, the high manganese steel in the as-cast structure is very brittle and cannot be used, so it needs to be treated by solution treatment. The commonly used heat treatment method is solution treatment, that is, heating the steel to 1050 ~ 1100 ℃, heat preservation to eliminate the as-cast structure, to obtain a single-phase austenite structure, and then water quenching to keep this structure to normal temperature. After heat treatment, the strength, plasticity and toughness of the steel are greatly improved.

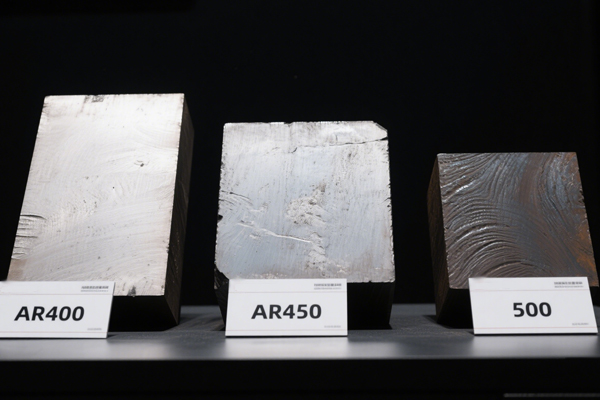

2. Medium and low alloy wear-resistant steel

This kind of steel has high hardness (Brinell hardness can reach HB500) and has weldability. The rolling method is usually used to make this type of steel into a steel plate or section steel, which is then welded into a member. Low-alloy steel used under the condition of wear as the main failure mode. Mainly divided into low-alloy welding wear-resistant steel, low-alloy wear-resistant steel for construction machinery parts and low-alloy wear-resistant steel for agricultural machinery.

3. Chrome Molybdenum Silicon Manganese Steel

Silicon-manganese alloy is an alloy composed of manganese, silicon, iron and a small amount of carbon and other elements. It is a ferrous alloy with a wide range of uses and a large output. Silicon-manganese alloy is a commonly used composite deoxidizer in steel making, and it is also a reducing agent for the production of metal manganese by low-carbon ferromanganese and electrothermal silicon in the production. Silicon-manganese alloy can be smelted in continuous operation in large, medium and small ore furnaces.

4. Special wear-resistant steel

Steel types used under specific working conditions, such as impact wear, corrosion wear, high temperature erosion wear, etc.

How to use wear-resistant steel

1. Cutting: Plasma cutting, carbon arc and grinding wheel saw can be used to cut the large-area multi-layer steel plate into the required shape. The best method is to use air or inert gas plasma arc for cutting. The recommended method is to start cutting from the alloy surface. Carbon arc cutting should start from the side of the substrate. If a saw blade is used, only straight-line cutting is required, and a silicon carbide saw blade is required.

2. Bending: The wear-resistant steel plate can be cold formed, and bent into the required shape, or arc or circle as required. Concave shape, the alloy crack will be closed due to inward stress; convex shape, the crack will become larger and crack, which is normal scene. If the crack is too large, use the corresponding electrode to repair. Crimp into a tube according to the recommended minimum bending radius.

3. Opening: Plasma cutting can be used for large holes, and EDM machine tools are recommended for small holes. Countersunk holes for mounting bolts can be cut with plasma or carbon arc.

4. Welding: The base metal of the large area composite steel plate is a steel plate with good weldability. When two steel plates are spliced, the back base metal can be welded together, and then the front surfacing layer is filled with the corresponding surfacing electrode. Evenly filled. Wear-resistant steel plates can also be welded to other steel structures.

5. Plug welding: plasma or carbon arc gouging can be used to make holes in the wear-resistant steel plate, and it can be connected to other steel structural parts by plug welding.

6. Bolt fixing: The bolt can be welded to the base material of the steel plate by flash welding or melting welding, and then connected to other workpieces, or holes can be made in the wear-resistant steel plate and connected to other workpieces by bolts;

7. Surface processing: The wear-resistant steel plate indicates that no processing is required. If processing is required, it can only be grinding. Other conventional methods are not applicable. Wear-resistant steel plate is not suitable for occasions with high surface accuracy requirements.