What is wear-resistant steel?

When steels rub against each other for a period of time, they wear out.

However, there are two types of wear: one intentional wear and one unintentional wear.

Intentional wear, such as sanding, grinding, sandblasting, etc., is deliberate wear based on need.

However, accidental wear will cause damage and other conditions.

Therefore, it is important to use appropriate materials to ensure that the wear of the steel surface will not cause damage to the parts.

Although steel has excellent wear resistance, not all steels have excellent wear resistance.

On the market, there are several types of steel that are specifically made to prevent wear, so they are also called wear-resistant steels.

How is wear-resistant steel made?

Similar to other types of steel, wear-resistant steel is made of iron ore, carbon and other alloying elements.

Iron ore is melted in the blast furnace to remove undesirable substances that may be present in the ore.

During this period, carbon and other alloying elements are added.

In wear-resistant steel, there are a lot of carbon and other alloying elements, such as chromium and manganese.

The addition of these alloy elements makes the steel less prone to wear.

In addition, alloy elements that prevent oxidation are added to the molten pool.

After the above steps are completed, the molten wear-resistant steel is formed, heat-treated, and cut.

The alloy element of wear-resistant steel is one of the reasons that makes it more wear-resistant than other steels.

Wear-resistant steel uses several alloys to improve wear resistance.

For example, carbon helps increase the hardness and strength of steel.

Chromium and manganese can help reduce wear.

Heat treatment is another factor in the wear resistance of steel.

Wear-resistant steel must have a microstructure that gives it high hardness.

This part is achieved by adding appropriate alloying elements.

However, this is not enough to ensure that it forms an appropriate microstructure.

Steel must also undergo a process of heating and rapid quenching to form a microstructure,

Care must be taken when welding and heating wear-resistant steels. If they are heated to a sufficiently high temperature, they may also have an annealing effect, resulting in a reduction in their hardness and therefore reduced wear resistance.

What wear-resistant steels are available?

There are several different wear-resistant steels on the market.

Each steel has a specific Brinell hardness value, because hardness is one of the most important factors to improve wear resistance.

While other steels may be more considered in the manufacture of tensile strength and toughness.

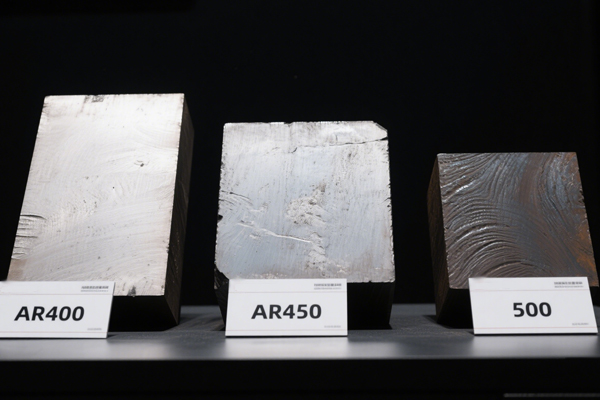

A common wear-resistant steel is AR400.

“400” indicates the Brinell hardness value.

AR450 and AR500 are similar to AR400, except that their Brinell hardness values are higher.

Although the Brinell hardness value of AR400 is lower, its formability is higher.

All three wear-resistant steels are used in mining equipment, cement pouring, forming equipment, excavating equipment and conveyor systems.