ELECTRO GALVANIZED STEEL

Electro Galvanlzed

Electro galvanized steel (EG steel, also known as EGI or cold galvanized steel) is a type of steel product coated with a layer of zinc through an electrolytic process. Here’s a detailed breakdown of its key aspects:

- Product name: ELECTRO GALVANIZED STEEL

- Standards: AISI,ASTM,DIN,JIS,BS,NB

- Grade: JIS G3313 (SECC, SECD, SECE) and ASTM A879/A591.

- Place of origin: Tianjin, China (Mainland)

- Brand name: Runfei

product Details

Electro Galvanlzed

Electro galvanized steel (EG steel, also known as EGI or cold galvanized steel) is a type of steel product coated with a layer of zinc through an electrolytic process. Here’s a detailed breakdown of its key aspects:

- Product name: ELECTRO GALVANIZED STEEL

- Standards: AISI,ASTM,DIN,JIS,BS,NB

- Grade: JIS G3313 (SECC, SECD, SECE) and ASTM A879/A591.

- Place of origin: Tianjin, China (Mainland)

- Brand name: Runfei

- Payment terms: L/C, T/T (30% deposit)

- Certifications: SGS,BV,IQI,TUV,ISO,etc.

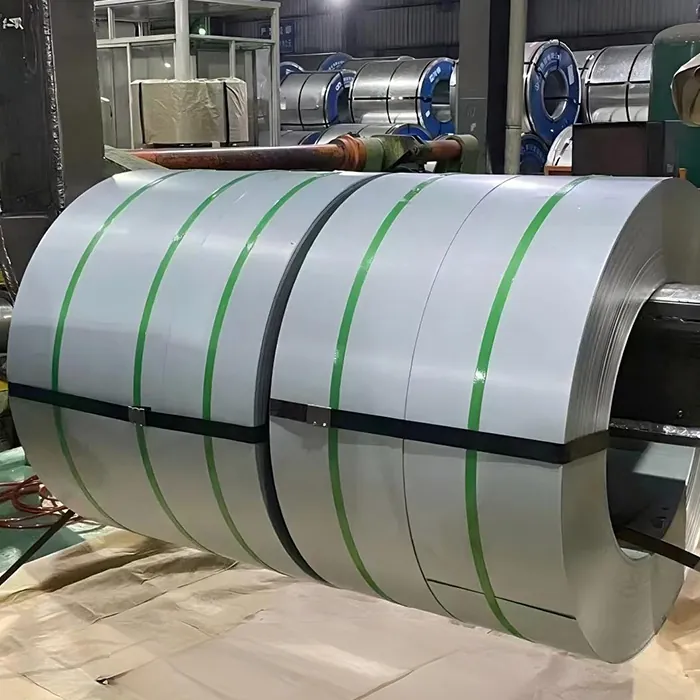

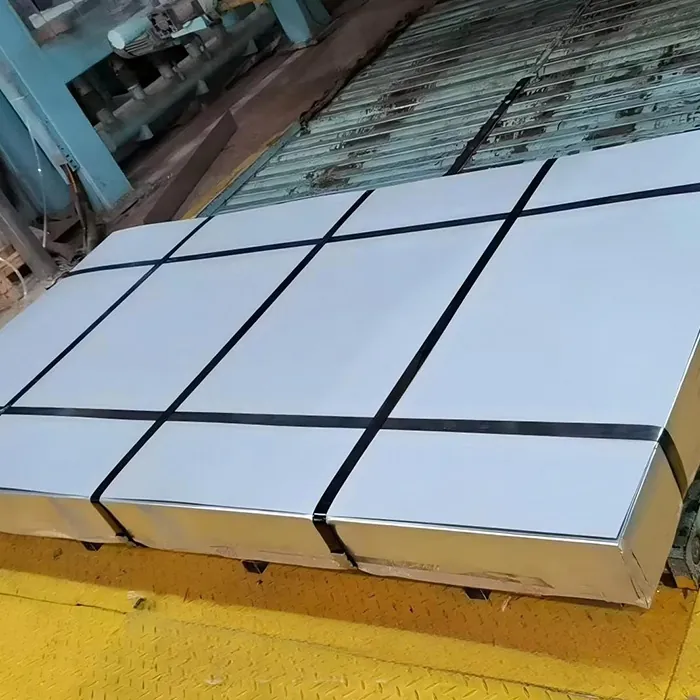

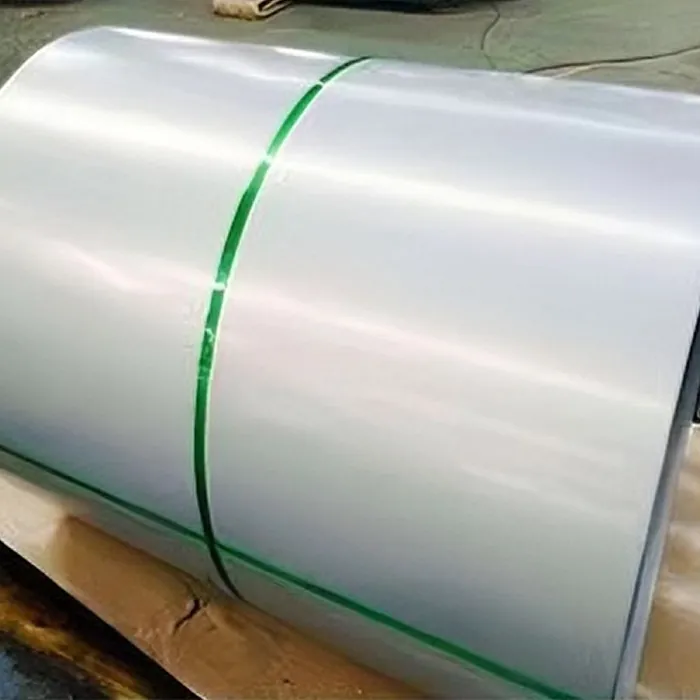

- Packing details: Standard seaworthy packing

Our Advantages

- We can provide factory price with trading company services

- We control production quality very strictly

- We guarantee 24 hours response and 48 hours solution providing service

- We accept small order quantity before formal cooperation

- We offer good quality with reasonable price, faster delivery with better payment terms

- We are ALIBABA credit checked supplier

- We offer ALIBABA trade assurance to protect your payment, product quality and on-time delivery

1. Manufacturing Process

It involves immersing cold-rolled steel in an electrolyte solution containing zinc salts and applying an electric current. Zinc ions are reduced and deposited onto the steel surface, forming a thin, uniform zinc layer (typically thinner than hot-dip galvanized steel).

2. Key Properties

Corrosion Resistance: The zinc coating acts as a barrier against moisture and corrosive elements. Even if the coating is damaged, a micro-battery effect forms between zinc and steel, protecting the steel substrate.

Surface Finish: It has a smooth, bright, and uniform appearance with no visible spangle, making it ideal for applications requiring aesthetic appeal or subsequent painting.

Formability & Weldability: The controlled zinc layer allows for excellent ductility, enabling processes like bending, deep drawing, and welding.

Thickness & Coating Weight:

Steel thickness: 0.12–3 mm (common range 0.3–2 mm).

Zinc coating weight: 10–275 g/m² (single side), with typical ranges of 10–30 g/m² for general use.

3. Specifications & Standards

Grades: Common grades include JIS G3313 (SECC, SECD, SECE) and ASTM A879/A591.

Surface Treatments: Options include chromate treatment, phosphate treatment, oiling, and fingerprint-resistant coatings.

4. Applications

Automotive Industry: Body panels, undercarriages, and internal components (benefits from lightweight and corrosion resistance).

Appliances: Casings for refrigerators, washers, dryers, and microwaves (requires both durability and aesthetic finish).

Electronics & Electricals: Computer cases, electronic equipment cabinets, and switchboards.

Construction: Indoor materials like acoustic ceilings, door frames, and light steel keels.

Furniture & Hardware: Shelving, office furniture, and various metal accessories.

5. Advantages vs. Disadvantages

Advantages

Aesthetically pleasing finish

Precise coating control

Excellent formability/weldability

Cost-effective for indoor applications

Disadvantages

Thinner coating limits outdoor durability (not ideal for harsh environments).

Slightly higher cost than some uncoated steels.

6. Industry Trends & Market

Global Production: China is the largest producer and consumer, with major players including Baowu Steel and Ansteel.

Growth Drivers: Demand from new energy vehicles (NEV), high-end appliances, and emerging sectors like 5G infrastructure and energy storage.

Sustainability: Trends include green technologies like chromium-free passivation and wastewater recycling to meet ESG standards.

This material balances performance, aesthetics, and cost, making it a staple in industries where both corrosion protection and visual quality are critical.