Prior to this, most people were not sure how to clean and maintain stainless steel. More often, they simply wiped with detergent and rags, but what you don’t know is that when you do It is possible that the protective layer on the surface of the stainless steel has been destroyed. Not only does it not maintain, but also shortens its service life, then whether it is brushed stainless steel or mirror stainless steel, how should any type of stainless steel be correct? What about maintenance and maintenance? The method I will tell you again, as follows:

The most common thing we see is that there is a layer of dirt on the surface of the colored stainless steel, and most of this layer of dirt is accumulated by the accumulation of smoke, dust, and stains over time, so we need to prepare a special stainless steel surface cleaner, and relatively fine Velvet rag.

1. Regular maintenance of cleaning agent

After the stainless steel decorative plate is used in a slightly humid environment for a period of time, a large amount of dust impurities will adhere to the surface, which is easy to produce electrochemical reactions, which will accelerate the corrosion of the material. The editor recommends that you use a special cleaning agent to clean the surface. Then dry it with a dry rag. The maintenance period is one month. The most important thing is to keep the surface of the board dry and cool.

2. Waxing

If you want to extend the maintenance cycle, this is not difficult. When we complete the regular maintenance of the cleaning agent, we can choose to wax the stainless steel surface. Waxing treatment is equivalent to adding a simple anti-rust layer on the stainless steel surface, but The effect can only be maintained for about three months, and the cost is not expensive, only ten to twenty yuan at a time.

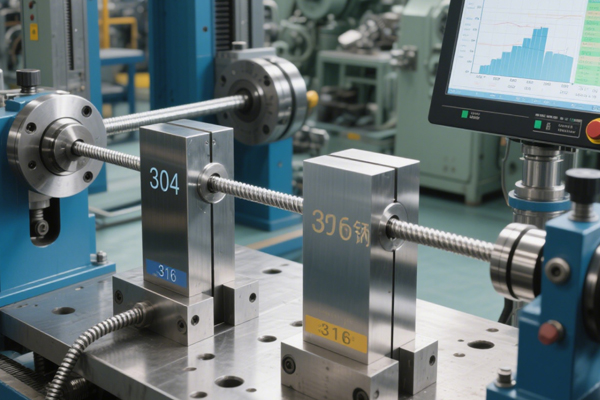

3. Surface treatment process

Although stainless steel has a certain corrosion resistance, it will eventually rust. The surface treatment process is equivalent to adding an anti-rust layer on the basis of the original performance. The effect is similar to waxing, but this anti-rust layer is always All exist, the process mentioned here is the electroplating process.

Another situation is that the stainless steel that has been put into use has been slightly rusted because it has not been maintained for a period of time. What should I do at this time? The method is as follows:

1. Removal of special rust remover

There are many special rust removers for stainless steel or metal materials on the market, and the price is not expensive. A bottle of tens of dollars can be used for more than half a year. The chemical elements in the rust remover react with the rust, thus To remove rust, this is the most direct and appropriate method.

2. White vinegar derusting method

This method is similar to the above method. It is worth noting that this method is suitable for stainless steel products with high frequency of daily use (stainless steel pots, stainless steel pots, stainless steel tableware, etc.), first pour white vinegar into it, press 1: Pour the water in the ratio of 1 and heat it to boiling, so that the rust will be decomposed by the white vinegar diluent, and then cleaned with a cleaning ball, the surface of the stainless steel will be as bright as new.