What Is AZ Sheet? Why GL Steel and alumina steel are the first choice for buyers all over the world?

In industrial materials, durable, cost-effective steel solutions are critical for construction, automotive, and manufacturing sectors worldwide. AZ sheet leads the way with high-performance alumina steel (also known as galvalume steel) and GL steel-but what makes these materials the first choice of global buyers? This guide breaks down their core definitions, competitive advantages, technical specs, and real-world applications, all backed by verified industry data.

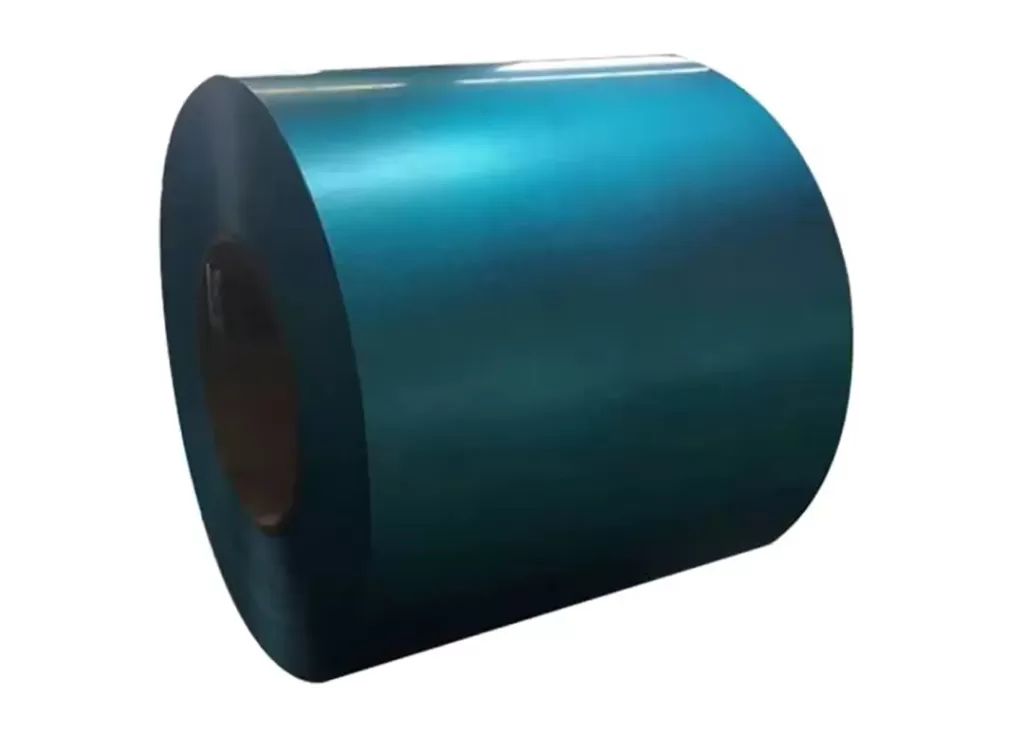

What is aluminum oxide steel and what is GL steel?

Aluminium steel: the core of corrosion resistance

Alumina steel is a kind of high-quality coated steel. The alloy layer is accurate: 55% aluminum, 43.3% zinc and 1.6% silicon. This balanced composition combines the dense oxide barrier of aluminum (to prevent corrosion) and sacrificial protection of zinc (to prevent scratching). It has been approved by ASTM A 792 and JIS G 3321, and it can maintain consistent performance in various environments.

GL steel: industrial standard terms

GL steel (short for galvalume) is synonymous with alumina steel all over the world, and it is very popular in Europe/Asia. Buyers use it to emphasize strength, durability and workability. Both of them refer to the same kind of coated steel with better performance than traditional galvanized steel in harsh conditions.

Why did AZ steel choose aluminum oxide steel and GL steel?

1. Unprecedented corrosion resistance

The corrosion resistance of aluminum oxide steel containing 55% aluminum-zinc alloy is 2-6 times higher than that of standard galvanized steel, and its service life is 15-30 years. For offshore engineering, the integrity maintenance time of GL steel is three times that of galvanized steel, thus reducing the maintenance costs.

2. Excellent thermal resistance

Alumina steel can withstand the high temperature of 315 degrees Celsius for more than 120 hours without damage. Galvanized steel degrades above 230 ° c, limiting its use in chimney pipes or solar frames. This makes AZ sheet GL steel the first choice of energy/manufacturing customers.

3. Cost effectiveness

Although the initial cost of alumina steel is high, its service life can save 20-30% of the total cost. Its lower density also increases the coverage per ton by 3%, reducing the transportation costs.

4. The service advantages of AZ steel

· Factory pricing+export support (tips for customs, documents and freight insurance).

· Zero compensation quality control: each coil is tested by ultrasonic wave (Source: AZ steel quality control protocol 2024).

· 24 hours response, 48 hours problem solving.

· The minimum order quantity of 25 tons is very suitable for testing aluminum and steel in small enterprises.

Specification for alumina coil of AZ steel

All coils meet ASTM A 792 and DIN 17162 standards and can be customized:

| Norm | AISI, ASTM, BS, DIN, GB, JIS, AS |

| Roughness | 0.4-2.5 mm (roof, panels, appliances) |

| Wide | 900-1500mm (customized for large-scale projects) |

| Galvanizing coating | 30-275g/i (the most common is 80-180g/i) |

| Weight of coil material | 3-8 tons |

| Coil numbers | 508/610mm (compatible with standard machines) |

| Superficial layer | Colored (scratch resistant) or finger resistant |

| Minimum quantity | Twenty-five tons |

| Package | Seaworthiness (horizontal/vertical, moisture-proof) |

| Harbor | Any port of China |

| Certificates | ISO 9001, SGS, RoHS |

Main Applications program

1. Architecture (70% of global demand in 2024)

Aluminum-steel is 40% roof and 30% cladding. Its reflectivity of ≥ 80% can reduce the cooling costs of green buildings by 15-20%. In 2019, a European industrial park was used for 2019—5 years, and there was no corrosion (Source: AZ steel project report 2024).

2. Home Appliances (15% demand)

Top brands use aluminum steel for refrigerator doors, air conditioning housings and washing machines. It’s over to stay attractive; Corrosion resistant and moisture resistant.

3. Automobile/industrial industry

GL steel is suitable for automobile seals and exhaust hoods (heat-resistant) Industrial uses: electrical cabinets, agri-equipment, chimneys.

How alumina steel coils are made.

AZ sheet’s three steps:

· Pre-Treatment: Uncoil, degrease (eco-solvents), heat (850–900 ° c) to remove oxides.

· Core Coating: dipped in 450 C alloy bath; The thickness is controlled by air knives, and then the water is cooled quickly.

· Post-Processing: Level, passivate (prevent rust), re coat (chromatic/anti-finger per order).

FAQ

Q 1: What are the corrosion and heat resistance of alumina and galvanized steel?

A1: Alumina steel (GL steel) has 2-6 times the corrosion resistance, heat resistance of 315 C and heat resistance of 230 C compared with galvanized steel.

Q 2: Can we customize galvanizing?

A2: It is the standard of-20-150g/m.

Q3: Does the product have a certificate of conformity?

A3: ISO 9001, SGS, RoHS. Provide regional certificates (ASTM A 792, BS EN 10346); Team helped to import the file.

Q4: when is the Delivery time?

A4: 15–30 days post-deposit (t/t 30% or l/c); For example, Tianjin-Rotterdam in 28 days and Tianjin-Los Angeles in 18 days.

Q5: Do you accept small orders?

A5: Yes—25-ton MOQ for testing.

Why does AZ steel stand out in alumina steel market

The global alumina steel industry will grow strongly, and it is estimated that by 2031, under the CAGR of 5.7%, the industry will reach 46.02 billion US dollars (Source: Grand View Research, 2024) -this trend is driven by the growing demand in the fields of construction, household appliances and automobiles. AZ sheet has positioned itself as a top partner in this expanding market, focusing on what buyers around the world value most: the combination of direct factory pricing and trade expertise (simplifying exports), zero compensation quality control (ensuring defect-free alumina coils) and 24/7 support for logistics or technical problems (keeping projects going normally).

Whether you need GL steel for a coastal construction project, customized alumina steel coils for equipment manufacturing, or a small trial order for testing performance, AZ sheet’s customized solutions can meet the needs of different industries. Please contact Runfei Steel Group’s sales team immediately for customized quotation or a sample for first-hand performance test.