I believe that everyone also knows the stainless steel material, and its corrosion resistance is its foothold in the material industry. In recent years, in order to adapt to more application scenarios, people are constantly developing new types of stainless steel models, which can be selected according to different uses. Appropriate models, stainless steel is now seen in various high-temperature scenes, then the question is coming, since people are specifically developing high-temperature resistant stainless steel, is it necessary to develop low-temperature resistant stainless steel? At low temperatures for color What is the impact of the performance of the stainless steel decorative plate? What will happen to the plate itself?

In the low temperature state, etc. applied to the housing of freezing appliances. Because ferrite stainless steel has a body-centered cubic structure, when the material performance is weakened, sharp cracks will quickly expand and cause brittle failure. Therefore, the 400 series does not have too outstanding low temperature resistance, and the 300 series austenitic stainless steel has a very good attainment in this regard, and listen to me what characteristics of austenitic stainless steel performance in low temperature environment.

According to relevant test reports, in the case of extremely low temperature, the tensile strength and yield strength of austenitic stainless steel will increase with the decrease of temperature, and the tensile strength has been significantly improved. Austenitic stainless steel will undergo a large amount of plastic deformation before fracture, so the material has less tendency to embrittlement;

At the same time, austenitic stainless steel also has a lower thermal conductivity and specific heat capacity, which means that as the temperature decreases, the thermal conductivity and specific heat capacity will also decrease; the relatively low thermal conductivity will reduce its low temperature Heat transfer, this will effectively reduce the heat loss of the material itself, thereby protecting the performance of the material at low temperatures.

The coefficient of thermal expansion of the metal causes the low-temperature storage tank to have different deformations at different temperatures, increasing the fatigue load of the low-temperature storage tank, so the low-temperature storage tank requires a smaller thermal expansion coefficient. For austenitic stainless steels, the coefficient of thermal expansion increases with decreasing temperature. Therefore, when welding austenitic stainless steel, in addition to meeting the requirements of mechanical properties, it is also necessary to select welding materials with equivalent thermal expansion coefficients.

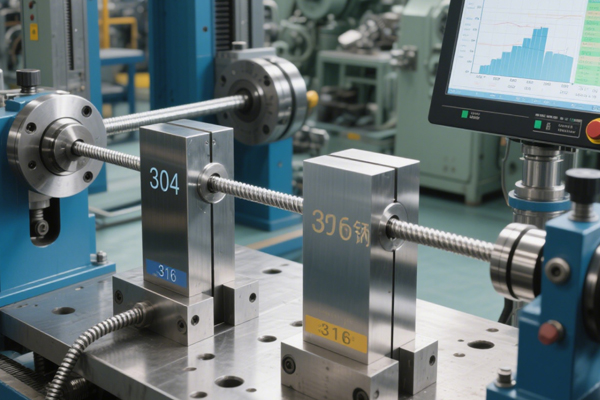

But even in low temperature environment, stainless steel can work properly. There are two important elements in stainless steel: nickel and carbon. Generally, when the nickel content reaches 3.5%, it can be used at a low temperature of -100°C. If the nickel content reaches 9%, there is no problem at all when used in a low temperature environment of -196℃. If the nickel content in the stainless steel material is high, the limit can reach -650℃, so 304 stainless steel is used as the theme material of the freezing storage tank It’s just right.