In the field of industrial materials, carbon steel has been the cornerstone for a long time because of its excellent versatility, durability and cost-effectiveness. Among the various grades of carbon steel, ASTM A653 mild carbon steel stands out as a preferred choice for numerous applications across construction, automotive, and manufacturing industries. According to the latest ASTM A653/A653 M-23 standard, the material has various specifications, including commercial steel, forming steel, deep-drawn steel and structural steel, each of which is tailored to specific application requirements. As a typical mild carbon steel grade, ASTM A653 combines the inherent advantages of carbon steel with the corrosion resistance of zinc coating, expanding its applicability in both indoor and outdoor environments.

But what exactly is ASTM A653 mild carbon steel and why should it be the first choice for your future projects? This guide delves into all the basic aspects of this material, from its definition and unique advantages to product specifications, application scenarios and main considerations when choosing carbon steel manufacturer.

What Is ASTM A653 mild steel?

First of all, let’s make clear the core definition. Mild carbon steel, also known as mild carbon steel, is a type of carbon steel with a carbon content ranging from 0.05% to 0.30% by weight. This mild carbon content endows it with excellent weldability, ductility, and machinability, distinguishing it from high-carbon steels that prioritize hardness over formability. ASTM A653 is a standard specification for galvanized (galvanized) or zinc-iron alloy coated (galvanized annealed) steel plates produced by hot dip plating process, covering steel coils and cut lengths. This standard, issued by ASTM International, can ensure that the material meets strict requirements for mechanical properties, coating quality and dimensional accuracy, so that it can remain reliable for a wide range of industrial applications.

The demand for ASTM A653 mild carbon steel is increasing, which is closely related to the strong development of the global carbon steel market. According to Statista’s report, in 2024, the global carbon steel market will be about 980 billion US dollars, and it is expected to reach 1,350 billion US dollars by 2030, with a compound annual growth rate (CAGR) of 5.4% from 2025 to 2030. The Asia Pacific region dominates the market, accounting for over 65% of the global share in 2024, driven by rapid infrastructure development and manufacturing recovery in countries like China and India. This data emphasizes the market potential of high quality carbon steel products like ASTM A653.

Unique advantages of ASTM A653 mild carbon steel

ASTM A653 mild carbon steel boasts a range of unique advantages that make it stand out among other carbon steel grades, making it a favorite for both manufacturers and end-users. The following are major advantages.

1. Excellent corrosion resistance

Hot-dipped zinc or zinc-iron alloy coating conforming to ASTM A653 provides strong corrosion protection, which is an important advantage for outdoor or harsh environment applications. The zinc coating acts as a barrier to prevent moisture and oxygen from reaching the steel matrix. In addition, after heat treatment, the alloying hot dip galvanized coating further improves its corrosion resistance, scratch resistance and residual stress resistance, and prolongs the service life of the material. This makes ASTM A653 suitable for outdoor signage, truck beds, and marine components.

2. Cost-Effectiveness

As a mild carbon steel, ASTM A653 is easier to produce than high-carbon steel or alloy steels. Its mild raw material and production costs, coupled with its excellent machinability (reducing processing costs), make it an economical and efficient scheme for large-scale projects. When purchasing from a reliable carbon steel manufacturer, it can provide high quality, balanced performance and budget requirements at a reasonable price.

3. Meet strict standards

ASTM A653 meets the strict requirements of ASTM A653/A653 M-23, ensuring the consistency of quality and performance. It also meets other international standards such as AISI, BS, DIN, GB and JIS, so it is suitable for global markets. In addition, the product of Runfei (a leading carbon steel manufacturer) have passed ISO 9001, SGS and RoHS certifications, which further verifies their quality and environmental protection.

4. Multifunctional Applications

The combination of machinability, corrosion resistance and cost-effectiveness makes ASTM A653 suitable for many industries. From buildings and automobiles to agricultural and electrical equipment, it can meet the needs of different projects, reducing the demand for various material types and simplifying supply chain management.

ASTM A653 production technology of mild carbon steel

The production of ASTM A653 mild carbon steel involves several key steps, each of which requires accuracy to ensure that the final product meets standard requirements. This is a step-by-step summary.

1. Raw material Selection: the main raw materials include high-quality iron ore, limestone and coke. Iron ore provides the iron content, limestone serves as a flux to remove impurities, and coke provides heat and reducing agents for smelting. A reliable carbon steel manufacturer will strictly choose raw materials to ensure the quality of basic steel.

2. Ladle Treatment: the steel is poured into a ladle for further treatment, including temperature regulation and alloy addition (if necessary) to enhance mechanical properties.

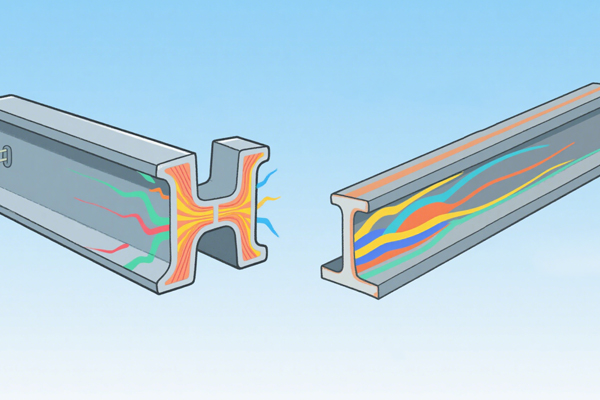

3. Casting and rolling: the refined molten steel is cast into slabs, and then hot rolled or cold rolled into the required thickness and width. In this step, the steel is made into a sheet or coils.

4. Hot-Dip Coating: the rolled steel is immersed in a molten zinc or zinc-iron alloy bath to form a protective coating. After additional heat treatment, the galvanized annealed steel forms an alloy between the zinc coating and the steel matrix, thus improving the adhesion and properties of the coating.

5. Quality Inspection: check the dimensional accuracy, coating thickness, mechanical properties and surface quality of the final product to ensure that it meets the ASTM A653 standards. After passing the inspection, we have obtained ISO 9001 and SGS certification.

Runfei ASTM A653 product specification of mild carbon steel

Runfei is a reliable carbon steel manufacturer located in Tianjin, China, providing high-quality ASTM A653 mild carbon steel with the following specifications. All products strictly conform to international standards and undergo strict quality control.

| Item | Specification Details |

| Product Name | ASTM A653 MILD CARBON STEEL |

| Standards | AISI, ASTM, BS, DIN, GB, JIS |

| Brand Name | Runfei |

| Place of Origin | Tianjin, China (Mainland) |

| Grades | ss400, a36, q235a/b/c/d, sphc, q195, sae1006, sae1008 |

| Size | 1.5mm-20mm * 1219mm-2000mm * C (coil) |

| Coil Weight | Max 8MT |

| Thickness Tolerance | +/-0.5mm |

| Width & Length Tolerance | +25mm/-0mm |

| MOQ | 24MT |

| Certifications | ISO 9001, SGS, RoHS Directive-compliant |

| Mill | Famous mill in China |

| Cargo Ready Date | 30-40 days after order confirmation |

| Latest Shipment | Within 45 days after order confirmation |

| Port | Xingang port, China |

| Packaging | Standard seaworthy packing (horizontal/vertical type available), naked by strips |

| Shipping | By container or breakbulk vessel |

| Payment Terms | 30% TT in advance and balance before shipment; 100% L/C at sight |

| Invoicing | Based on actual weight |

Main application occasions of ASTM A653 Mild carbon steel

The versatility of ASTM A653 mild carbon steel makes it suitable for a wide range of applications in many industries. The following are the major application scenarios supported by industry insights.

1. Buildings and Infrastructure

In the construction industry, ASTM A653 is widely used for structural parts, building fixtures, outdoor signs and garage doors. Its strength, solderability and corrosion resistance make it ideal choice for outdoor structures exposed to the natural environment. For example, it is used in building frames, mounting plates and decorative building components. According to the data of Grand View Research, the construction industry accounts for 38.1% of the global carbon steel market demand, which makes ASTM A653 a key material in this field.

2. Automobile Industry

The automobile industry relies heavily on ASTM A653 to produce truck compartment components, tool boxes, body panels and chassis parts. Its excellent formability allows for the creation of complex shapes, while the zinc coating protects against corrosion from road salt and moisture. With the growth of the electric vehicle market, ASTM A653 is also increasingly used in battery pack components, aligning with the industry’s shift towards lightweight and durable materials.

3. Manufacturing and Industrial Equipment

ASTM A653 is used to produce all kinds of industrial equipment, including vending machines, trash cans, heating and cooling systems and electrical protection components. Its machinability and cost-effectiveness make it suitable for large-scale production projects, while its corrosion resistance ensures its long-term performance in industrial environment. Agricultural equipment, such as farm implements, also benefits from its durability and machinability.

4. In the field of renewable energy

As the development of renewable energy industry, ASTM A653 has new applications in wind turbine components and solar panel supports. Its corrosion resistance is critical for outdoor renewable energy equipment exposed to harsh weather conditions, and its formability allows for the production of custom-shaped components. The increasing demand for renewable energy sources is expected to promote the further application of ASTM A653 in this field.

Frequently asked questions about ASTM A653 mild carbon steel

In order to help you make informed decisions, the following are frequently asked questions about ASTM A653 mild carbon steel and choosing reliable carbon steel manufacturer.

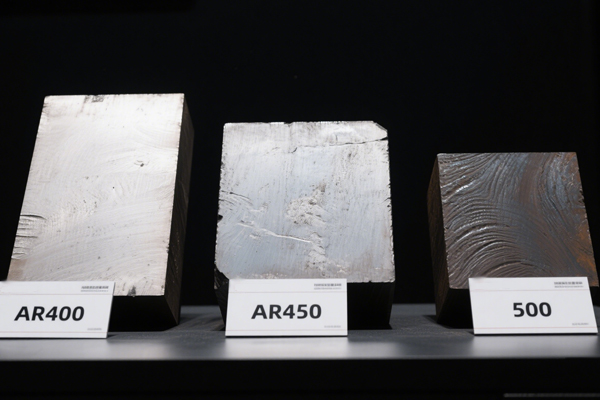

Q1: What is the difference between ASTM A653 galvanized steel and alloyed galvanized steel?

A: Galvanized steel has a pure zinc coating applied by hot dip plating, which provides excellent corrosion resistance. The galvanized annealed steel is subjected to additional heat treatment after galvanizing to form zinc-iron alloy coating. Alloyed hot dip galvanized steel has better paint adhesion, scratch resistance and residual stress resistance, which makes it suitable for applications that need painting or stamping. Galvanized steel is the first choice for applications that give priority to maximum corrosion resistance without painting.

Q 2: how to ensure the quality of ASTM A653 mild carbon steel during procurement?

A: Choose famous carbon steel manufacturer with relevant certifications (ISO 9001, SGS, RoHS). Quality inspection report is required, including mechanical property tests (yield strength and elongation) and coating thickness tests. Verify whether the product meets the ASTM A653/A653 M-23 standards. Runfei, for example, implements strict quality control throughout the whole production process to ensure zero compensation for quality problems.

Q 3: Can ASTM A653 mild carbon steel be used in high temperature environment?

A: ASTM A653 is not recommended for continuous high-temperature environments above 200 ° c, as the zinc coating may degrade, reducing corrosion resistance. For high temperature applications, consult a carbon steel manufacturer for heat-resistant carbon steel grades or other heat treatment options.

Q 4: what are the terms of payment and delivery of ASTM A653 mild carbon steel from runfei?

A: Runfei provides flexible payment methods: 30% TT in advance, and the balance will be paid before shipment, or 100% sight letter of credit. The goods will be ready within 30-40 days after order is confirmed, and will be delivered within 45 days at the latest. Sea transportation can be done by container or bulk carrier from China Xingang. Accept small orders before formal cooperation and provide Alibaba trade guarantee to protect payment, quality and on-time delivery.

Q 5: Is ASTM A653 mild carbon steel recyclable?

A: Yes, carbon steel is highly recyclable and ASTM A653 is no exception. The zinc coating can be separated in the recycling process, and the steel can be reused to produce new carbon steel products. Recovering carbon steel can reduce energy consumption and environmental impact, which is in line with global sustainable development goals.

Summary

ASTM A653 mild carbon steel is a versatile, cost-effective, and reliable material that meets the needs of numerous industries. Its excellent machinability, corrosion resistance and strict standards make it the first choice for construction, automobile, manufacturing and renewable energy projects. When working with a trusted carbon steel manufacturer like Runfei, you can be sure to get high quality products, flexible terms and professional support.

Whether you are engaged in large-scale construction project, manufacturing auto parts or expanding the production of renewable energy equipment, ASTM A653 mild carbon steel is a wise investment. Please contact Runfei immediately to learn more about their ASTM A653 products and how they can support your project requirements.