[Key Takeaway] As global demand for renewable energy continues to surge, the photovoltaic industry is booming. At its core, photovoltaic glass is emerging as a crucial “transparent armor” in building a greener future, thanks to its unique technological appeal and pivotal role. This specialized glass, capable of converting solar energy into electricity, is not just a testament to technological innovation but also a vital component in the future energy landscape.

From Sand to Power: Unveiling the Birth of Photovoltaic Glass

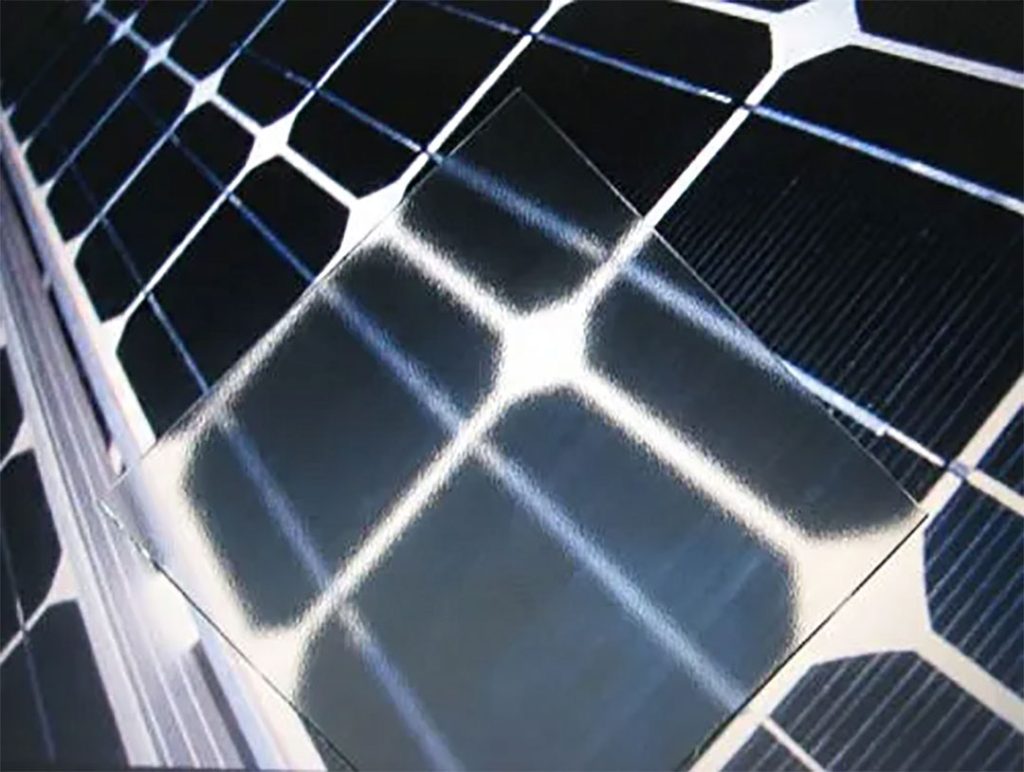

Photovoltaic glass, also known as “PV glass” or “solar glass,” is far from ordinary construction material. It’s a precisely engineered composite consisting of a glass substrate, solar cells, encapsulant films, backsheets, and special metal wires. Its primary raw materials, such as quartz sand, provide the robust skeleton of the glass, while soda ash helps lower the melting point, and limestone adjusts the glass’s viscosity, ensuring smooth molding during production.

PV glass is typically manufactured using the rolling method, a process that shapes molten glass. At temperatures as high as 1100°C, the molten glass is precisely controlled by rolling machines to form glass sheets of uniform thickness, specific patterns, and a high light transmittance of 91.5%. Subsequently, these raw sheets enter an annealing furnace, where precise temperature control eliminates internal stresses, giving the glass stable strength and making it easy to cut and process. It’s worth noting that the production lines for patterned PV glass are unique and cannot be directly interchanged with traditional float glass lines, highlighting their specialization and technical barriers.

After raw sheet production, PV glass undergoes deep processing:

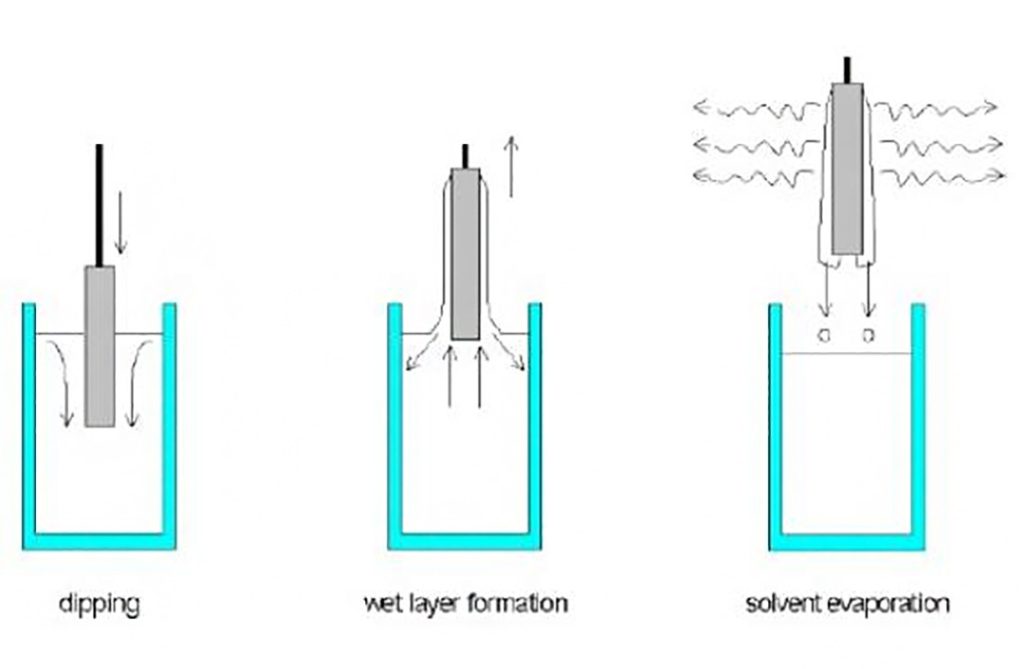

· Coating: To further enhance the glass’s light transmission, its surface is coated with one or more special films, ensuring maximum capture of sunlight.

· Tempering: Tempering significantly improves the glass’s mechanical strength and safety. Its bending strength is 3-5 times that of ordinary glass, and its impact strength is even 5-10 times higher, giving PV modules greater resilience against harsh environmental conditions.

Protection and Conversion: The Core Mission of Photovoltaic Glass

In a photovoltaic module, PV glass plays a dual role:

1. The Robust Guardian: It acts as a tough, transparent shield, tightly encapsulating and protecting the module’s crucial crystalline silicon cells from external damage caused by wind, rain, dust, and other environmental factors.

2. The Efficient Energy Guide: The primary task of PV glass is to maximize the transmission of sunlight to the silicon cells. Every ray of sunlight that passes through the glass is converted into valuable electrical energy by the silicon cells, ultimately contributing to clean power that lights up homes and businesses.

Cutting-Edge Technology: From Ultra-Clear to Anti-Reflective, Constantly Pushing the Limits of Light Transmission

Currently, PV glass primarily falls into categories such as ultra-clear patterned PV glass (also known as ultra-clear rolled PV glass), ultra-clear processed float glass, TCO glass, and backsheet glass. Among these, ultra-clear rolled glass is a market leader, characterized by its ultra-high light transmittance (over 98% visible light transmission) and extremely low iron content. What you see is no longer the greenish tint of traditional glass but an ultimate, crystal-clear transparency. This type of glass efficiently absorbs solar energy, significantly improving photoelectric conversion efficiency. It also boasts excellent strength and weather resistance, ensuring the module’s durability in various challenging environments.

However, technological progress is relentless. Building on ultra-clear rolled glass, anti-reflective (AR) PV glass has emerged. This innovative product uses special films coated on the glass surface to reduce light reflection. Through processes like vacuum deposition, etching, or high-temperature sintering, one or more anti-reflective layers are formed on the glass surface. Notably, the etching method, due to its economical and straightforward advantages, can increase the glass’s light transmittance by an additional 4%-5%. For example, 3mm thick glass can see its transmittance rise from 80% to 85%, and ultra-clear glass with lower iron content can even go from 86% to 91%. This AR coating forms a strong bond with the glass and exhibits excellent abrasion resistance, directly boosting the overall power output of PV modules and bringing tangible benefits in terms of efficiency and cost reduction to the solar industry.

[Outlook] As a critical material in the new energy sector, the continuous iteration and upgrading of PV glass technology are steadily driving improvements in solar power generation efficiency and reductions in cost. In the future, with the emergence of more innovative materials and processes, PV glass, in lighter, more efficient, and diversified forms, will continue to play an indispensable role as the “transparent heart” in building a sustainable society.

Picture source:

1. Xinyi solar

2. Qichacha, Frontier Research Institute