In modern industrial and architectural fields, when it comes to versatile and reliable materials, few names are as ubiquitous as 304 stainless steel. At the kitchen sink to the exterior wall of skyscrapers, the core of countless applications is a basic form of this alloy: the 304 stainless steel coil. But what exactly is it and what makes it so special? This article discusses the properties, advantages and uses of this basic material in depth.

Defining the 304 Stainless Steel Coil

A 304 stainless steel coil is a kind of continuous rolled 304 steel strip, which is rolled into a coil for effective storage, transportation and processing. The “304” refers to its specific chemical composition, which is globally uniform. It is part of the 300 series stainless steel, which is austenitic stainless steel and is famous for its excellent corrosion resistance and formability.

The unique advantages of 304 stainless steel

The popularity of 304 steel is not accidental. It provides a balanced set of attributes, making it suitable for a variety of environments.

1. Excellent corrosion Resistance: this is its most obvious advantage. 304 stainless steel has a strong resistance to all kinds of atmospheric environment and many corrosive media. It performs very well in moderate industrial, rural and coastal environments. A study on Nickel Institute confirms that the corrosion rate of austenitic stainless steel like 304 in many common environments is less than 0.1 mm per year, thus ensuring long-term structural integrity. (Source: Nickel Institute, “Stainless Steels and Alloys: Why They Resist Corrosion”).

2. High Formability and Fabrication Ease: the austenitic structure of 304 steel allows it to be deeply drawn, bent, and formed into complex shapes without cracking. This makes 304 stainless steel coil the first choice for the production of sinks, tableware and building components.

3. Hygienic and easy to Clean: the non-porous smooth surface of 304 stainless steel can prevent the adhesion and growth of bacteria and mold, making it the first choice for food processing equipment, kitchen utensils and medical instruments.

4. Aesthetic Appeal: With a range of available surface finishes—from the standard 2 b (cold-rolled, annealed, and pickled) to BA (Bright Annealed), and No.4 (brushed) —304 steel offers both a modern, clean look and the ability to hide minor scratches and fingerprints.

5. Strength and Durability: Despite being easy to form, 304 stainless steel offers good mechanical strength and high impact strength, even at cryogenic temperatures.

Product Specifications: Take a closer look at Runfei 304 coil

To provide a concrete example, let’s check the specifications of 304 stainless steel coils of a famous manufacturer like Runfei. This transparency helps buyers to make informed decisions.

Standards: in line with AISI, ASTM, BS, DIN, GB and JIS standards, ensuring global acceptability.

Material Grades: mainly 304, but also other grades, such as 304L, 316,316L and 321.

Thickness: Ranges from 0.25 mm to 3.0 mm.

Width and length: the standard width can reach 1219 mm, and the lengths can reach 4000 mm. The sizes can be customized.

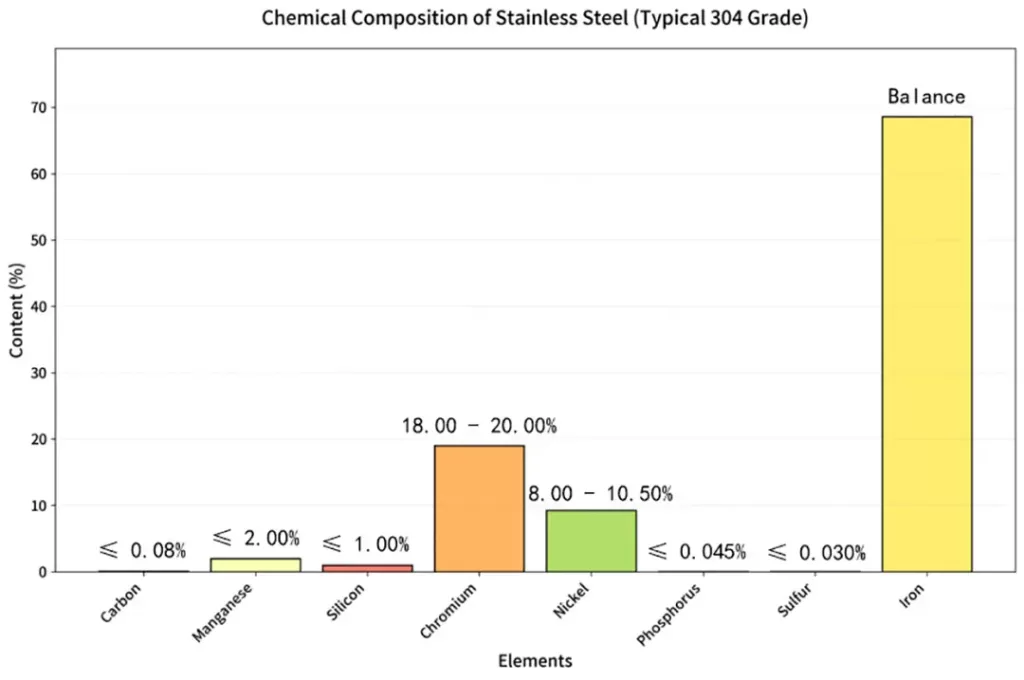

The following figure illustrates the typical chemical composition of AISI 304(data comes from ASTM A 240 standard).

Main application scenarios of 304 stainless steel coil

The versatility of 304 stainless steel coil allows it to be manufactured into countless end-use products. The main application include:

- Architecture and construction (building decoration, luxury doors, elevators): Its corrosion resistance and aesthetic elasticity make it perfect material for covering, roof, decoration and elevator interiors. Even in harsh urban environment, stainless steel can maintain its appearance.

- Transportation (Ship Building, Train Interiors): Used for interior paneling, trim, and components in ships and trains due to its strength-to-weight ratio and fire resistance.

- Food and Beverage Industry: storage Tanks, pipelines and food processing machinery are usually made from 304 steel, because it will not produce flavor and will not be corroded by edible acids.

- Kitchen and catering equipment: Sinks, countertops, cookers and tableware are mainly made from 304 stainless steel because it is hygienic and durable.

- Chemistry and pharmacy: 316 stainless steel may be recommended for equipment that needs good corrosion resistance to various chemicals, although for more corrosive environments.

According to a market report by Grand View Research, the construction industry is the largest end user of stainless steel, accounting for more than 25% of global consumption in 2022, of which Grade 304 is the main contributor. (source: Daguan Research, “Scale, Share and Trend Analysis Report of Stainless Steel Market”).

Frequently Asked Questions

Q1: What is the difference between 304 and 304L stainless steel?

A: the main difference lies in carbon content. The carbon content of 304L is relatively low (the carbon content of 304 is ≤ 0.03%, while the carbon content of 304 is ≤ 0.08%) This makes 304L more resistant to “sensitization” (carbide precipitation at grain boundaries) in the welding process, which can lead to intergranular corrosion. For most applications, 304L is enough, but 304L is more suitable for large-size welded parts.

Q 2: Is stainless steel magnetic?

A: Normally, austenitic 304 stainless steel is non-magnetic in the annealed state. However, cold working (such as bending or cutting) can cause a slight magnetic response in the material.

Q 3: How does 304 stainless steel compare to 316 stainless steel?

A: 316 stainless steel contains molybdenum (2-3%), which greatly improves its corrosion resistance, especially to chloride and acid in marine and more corrosive industrial environments. 304 steel is more cost-effective, and is completely suitable for most standard applications.

Q 4: How long is the service life of a product made from 304 stainless steel?

A: Life span is highly dependent on environmental factors. In a mild indoor environment, if properly cared for, it can continue to be used indefinitely. In a corrosive coastal or industrial environments, it can still last for decades without significant degradation. As long as oxygen exists, its passivation layer will repair itself when it is scratched.

Summary

The 304 stainless steel coil is the proof of excellent material engineering. Its balanced characteristics of corrosion resistance, moldability, strength and hygiene make it an indispensable resource across countless industries. Whether purchasing from a global giant or a quality-focused manufacturer like Runfei, Runfei’s advantage lie in strict quality control, ISO 9001 and SGS certification and flexible order terms. Knowing the specifications and performance of 304 steel is very important for any project that needs durability and reliability. Undoubtedly, this is the main force in the field of the stainless steel.