Products Descriptions

● Product name: Zinc Coating Corrugated Sheet

● Standards: AISI, ASTM, BS, DIN, GB, JIS

● Place of origin: Tianjin, China (Mainland)

● Brand name: Runfei

● Payment terms: L/C, T/T (30% deposit)

● Certifications: ISO 9001, SGS, RoHS Directive-compliant

● Packing details: Standard seaworthy packing, horizontal type and vertical type are all available

Our Advantages

● We can provide factory price with trading company services

● We control production quality very strictly to keep none compensation

● We guarantee 24 hours response and 48 hours solution providing service

● We accept small order quantity before formal cooperation

● We offer good quality with reasonable price, faster delivery with better payment terms

● We have professional teams and the factory

● It’s very important for a company to be honest in the process of trading and so do we

1. Finish As with almost any product the finish of the galvanized metal finish will change over time. After a period of time, the surface will appear to have a white oxide look. When this happens the material is actually protecting itself from further damage. We stock and sell several corrugated and decking panels in either a (G-60) or (G-90) level of galvanizing.

2. Main Structure

A normal steel sheet will rust almost immediately, but galvanizing will protect the steel. This galvanized, eltro-coated, hot-dipped process produces a silvery look or spangled finish. As a standard, several of our industrial metal siding, metal roofing, metal decking, corrugated metal panels and accessories are made in galvanized steel 3. Application Scope It is most commonly used for commercial, agricultural, and industrial purposes, however, it is now also being recognized as an excellent form of residential roofing 4. Main Features 1) Combine excellent barrier corrosion protection of aluminum with galvanic protection of zinc 2) Preferred product for long-term resistance to atmospheric corrosion 3) Superior corrosion resistance 4) Easy to install, high strength and lower costs 5) It is widely used as walls or roofs for factories, warehouses, garages, exhibition centers 5. Installation Tips 1) Prepare roof surface by removing old roofing, rotten wood,adding roofing felt to entire surface 2) Calculate the sheet numbers needed. Divide the area of your roof by size of sheets 3) Place your first metal sheet in a corner of the roof, flush against the surface 4) Nail in the first metal sheet to the wood of the roof 5) Place the second metal sheet alongside the first with an overlap of 3 to 4 inches (10 cm) 6) Nail the second metal sheet to the roof 6. Tools you’ll need when install galvanized steel corrugated sheet 1) Sheets of corrugated metal

2) Metal ridge caps

3) Roofing felt (if needed)

4) Nails

5) Hex screws

6) Washers

7) Hammer

8) Drill

| Commodity | Galvanized Metal Roofing Sheet |

| Standard | ASTM A653M-04/JIS G3302/DIN EN10143/GBT 2518-2008 |

| Base Plate | Cold rolled steel coil, hot dipped galvanized steel coil |

| Zinc Coating | Z30-Z275G/m2 |

| Thickness | 0.12-1.5mm |

| Width | 750-1250mm(beforecorrugation) 600-1000mm(after corrugation) |

| Wave depth | 18(+/-2mm) |

| Wave distance | 76(+/-2mm) |

| Length | 1800-5200mm |

| Number of corrugation | 9-12 |

| Products Feature | water resistance, light weight, easy installation, aesthetic, high tensile |

| Packing | standard export water-proof package with steel strips fixed |

| Delivery time | 25-45 days after confirmation |

| Weight per Steel Pallet | 3 Metric Tons |

| MOQ | 25 Metric Tons |

| Application | exterior and interior wall,roofs,and soffits |

| Qualification | ISO9001-2000Certificate |

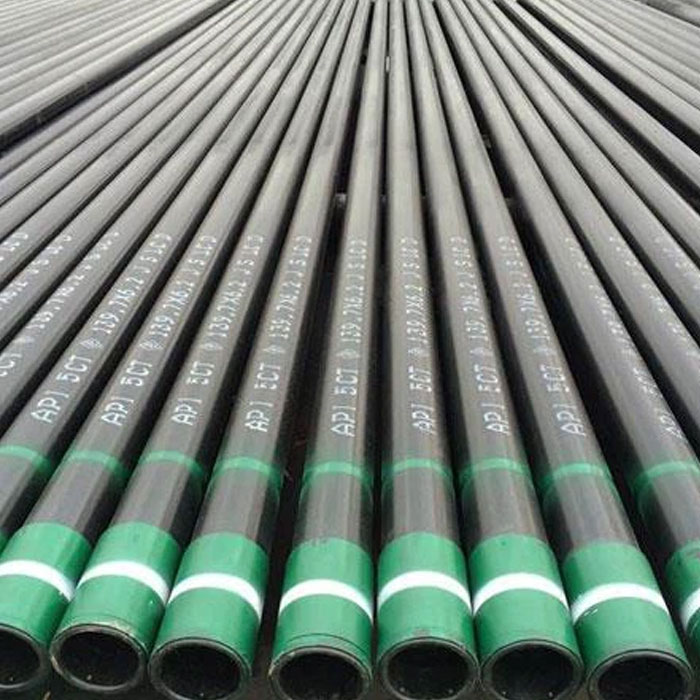

Hot Tags: hot rolled structural pipe, China, suppliers, manufacturers, factory, price, quotation, high quality, Hot Rolled Structural Pipe, Petroleum Coupling Tube, Hot Roller Automobile Half Axle Sleeve, Gi Corrugated Sheets, Hot Rolled Ejector Pins Steel, Hot Rolled Fluid Piping.