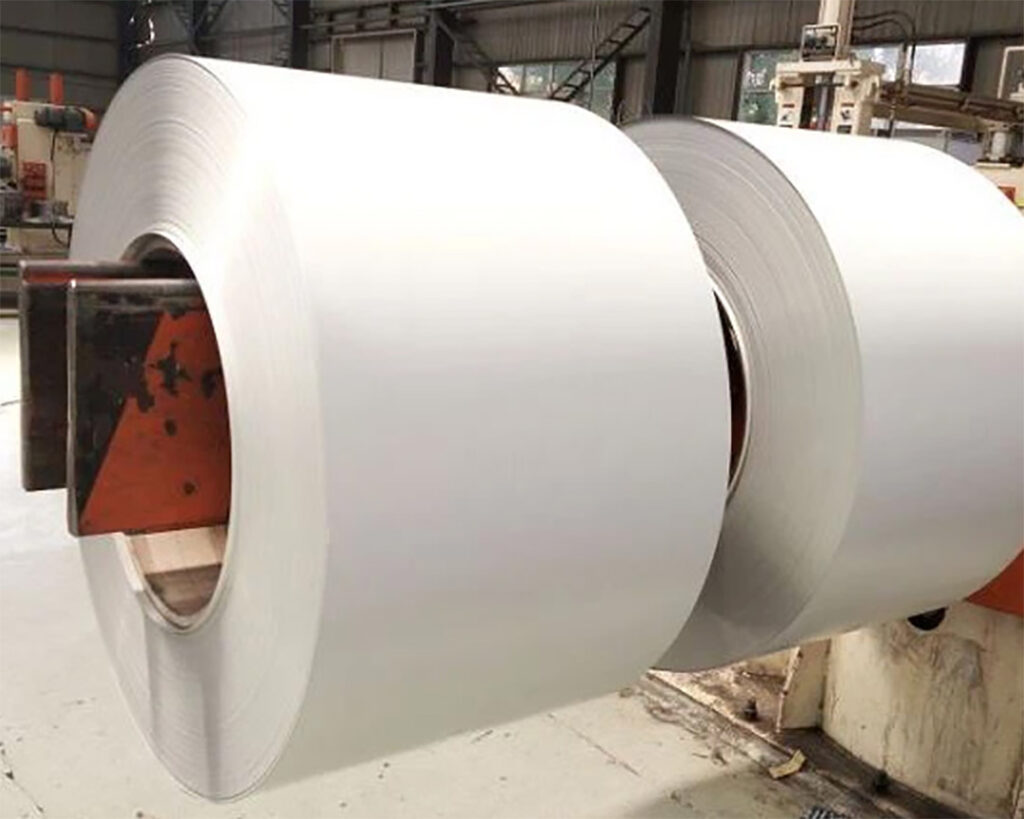

In the industrial sector, demand for durable, high-performance materials has driven the popularity of Anti Finger Galvalume Steel Coils. Thanks to the combination of Galvalume and high-quality hot-rolled steel substrate, these coils have performed well in all walks of life. Whether it is used for bridges, trucks or agricultural equipment, Anti Finger Galvalume steel coils (made of Galvalume and hot rolled steel) meet industry standards and are the first choice in the world.

What Are Anti Finger Galvalume Steel Coils?

Anti Finger Galvalume Steel Coils feature a specialized anti-fingerprint coating applied to Galvalume-treated steel, usually with a hot rolled steel base.

Galvalume (55% aluminum, 43.4% zinc, 1.6% silicon) offers exceptional corrosion resistance, outperforming traditional galvanized steel in harsh environments. The anti-fingerprint layer can prevent ugly marks and stains, which is very important for applications that pay attention to appearance and cleaning ability.

The hot rolled steel substrate has important mechanical properties: ductility, weldability and formability. Common hot-rolled steel used here can be bent, formed and welded, so that manufacturers can form coils into different parts without losing durability.

Unique Advantages of Anti Finger Galvalume Steel Coils

Anti Finger Galvalume Steel Coils (integrating Galvalume and hot rolled steel) boast standout benefits.

· Long-term corrosion protection: The Galvalume coating forms a tight oxide layer, shielding against moisture, salt, and weather—ideal for outdoor use like building facades.

· Enhanced structural integrity: hot rolled steel (e.g. A 1011 CS Type B) supports bending, forming and welding, ensuring durability of manufactured parts.

· Practical anti-fingerprint layer: it is unnecessary to clean fingerprints frequently, saving the manufacturing time of household appliance or retail fixture.

· Cost-effectiveness: Galvalume‘s protection combined with affordable hot rolled steel provides high performance without premium.

Product Specifications of Anti Finger Galvalume Steel Coils

Anti Finger Galvalume Steel Coils come in specs tailored to industrial needs, based on hot rolled steel (or cold-rolled) substrates, plus Galvalume and anti-fingerprint layers.

1. Hot Roll Commercial Steel

A 1011 CS Type B (CQ) is the key hot rolled steel grade here, with a max 0.15% carbon for formability and weldability. It is suitable for non-structural parts that need to be bent/formed (e.g. Electrical parts, lamps and lanterns).

Coils are available as standard Hot Roll or Hot Roll Pickled & Oil (scale-free, oiled for better coating adhesion). Note: This hot rolled steel isn’t for structural use—best for light-duty applications.

2. Structural Hot Roll Steel Grades

For the requirement of high strength, coils is made of structural hot-rolled steel substrate, which is corrosion-resistant with Galvalume.

· ASTM A 36: Widely used hot-rolled steel with minimum yield strength of 36 KSI (250 MPa). Ideal choice for welding/bolting bridges, buildings and structural components. Painted with Galvalume, suitable for outdoor uses such as railings. General applications: rail cars, trucks, agricultural equipment.

· A 1011-F HSLAS GR 50/GR 80: High-strength low-alloy (HSLAS) hot-rolled steel containing alloying elements for improving yield strength. Provide strength-to-weight ratio savings, formability and weldability-very suitable for truck frames and crane booms. Galvalume corrosion resistance; Anti-fingerprint technology can keep a high contact areas clean.

· A 1018 has-F GR 50: Hot rolled HSLAS steel with thick gauge for heavy parts (for example. Excavator arms). Maintain strength, formability and weldability-combine with coatings to improve durability.

· ASTM A 572 GR 50: High-strength low-alloy hot-rolled steel has higher strength, ductility and weldability than common carbon steel. For structural coils (buildings and bridges), it is cost-effective. Supplementary specifications (impact toughness, tensile strength) can be provided as required.

· A 656 GR 80: High-strength hot-rolled steel used for truck frames and crane booms. Providing improved moldability; It is provided in the form of a roll for coating. Galvalume salt resistance; Anti-fingerprint helps to maintain.

3. Cold Rolling Stage

A 1008 CS Type B (cold-rolled) suits applications needing smooth finishes (e.g. Electrical appliances, display cabinets). It supports bending/forming but isn’t for structural use—paired with Galvalume and anti-fingerprint layers for aesthetics and protection.

Major application scenarios

Anti Finger Galvalume steel coils (supported by Galvalume and hot rolled steel) are used in various industries.

Construction

Structural hot-rolled steel (ASTM A 36/a 572 GR 50) is used for building frames, bridges and external walls. Galvalume is weathering resistant; Anti-fingerprint and keep the handrails clean. The weldability of hot-rolled steel accelerates the assembly speed.

Transportation

Trucks (a 656 GR 80 coils) depends on the strength of hot rolled steel and the salt resistance of Galvalume. Trailers/railway vehicles use ASTM A 36/A 1011-F coils-balance strength and weight. Anti-fingerprint simplifies the maintenance check.

Agricultural

Tractors, harvester, and silos use hot rolled steel (a 1011 CS Type B/a 572 GR 50) coils. Galvalume can prevent water/fertilizer erosion; Hot rolled steel‘s formability enables custom parts. Anti-fingerprinting reduces dust, and the farms is clean.

Household appliances/consumer Goods

A 1011 CS Type B/a 1008 CS Type B coils are used for appliance parts (refrigerator doors) and display fixtures. Galvalume rust prevention; Anti-fingerprint maintenance appearance. The formability of hot-rolled steel makes it possible to innovate the designs.

Heavy machinery and equipment

Cranes/excavators use high-strength hot rolled steel (a 1018 has – F GR 50/a 656 GR 80) coils. Hot-rolled steel can bear heavy loads; Galvalume resists job-site corrosion. Anti-fingerprint technology makes control clearly visible.

Conclusion

Anti Finger Galvalume Steel Coils are versatile, high-performance materials, thanks to the Galvalume and hot rolled steel synergy. The anti-fingerprint layer increases the practicality, while the specifications (from commercial to high-strength hot rolled steel) meet different requirements.

Whether building bridges, manufacturing trucks or producing equipment, Anti Finger Galvalume steel coils are durable and valuable-supported by the mature performance of Galvalume and hot rolled steel, making them the first choice for competitive markets.