AZ steel is a highly sought-after metal solution for industrial and construction needs, driven by its core components: aluzinc steel and galvalume. These alloy-coated steel variants constitute the performance pillar of AZ steel, making it more popular than traditional steel. This paper explains the advantages, main specifications, applications and details of AZ steel, aluzinc steel and galvalume.

What Is AZ steel? With aluzinc steel and Galvalume as the center

AZ steel refers to aluminum-zinc alloy coated steel, in which aluzinc steel and galvalume play an important role. Aluzinc steel and galvalume are often used interchangeably, and they are both steel plates/coils coated with 55% aluminum, 43.4% zinc and 1.6% silicon. This kind of engineering alloy combines the best characteristics of aluminum and zinc, which is superior to a single metal coatings.

Different from galvanized steel (which only depends on zinc), aluzinc steel and galvalume take advantage of the corrosion resistance of aluminum and the sacrificial protection of zinc. Exposure to the natural environment will form a dense alumina layer, which will block moisture and chemicals, making aluzinc steel and galvalume (AZ the core of AZ steel) more durable in harsh conditions.

Unique advantages of AZ steel: aluzinc steel and Galvalume drive

The advantages of AZ steel come from the excellent properties of aluzinc steel and galvalume. The following are the main advantages.

1. Excellent Corrosion Resistance

Corrosion can damage steel, but aluzinc steel and galvalume have solved this problem. The 55% of the aluminum forms an impermeable oxide; Even when scratched, zinc is a sacrificial anode. Tests confirm aluzinc steel and galvalume offer 2-6 x greater corrosion resistance than hot-dip galvanized steel, lasting decades in outdoor/high-humidity areas (coastal zones, industrial sites).

2. Excellent heat Resistance

Galvalume (AZ the key component of AZ steel) is resistant to high temperatures, unlike galvanized steel (which peels off above 200 degrees Celsius) aluzinc steel and galvalume maintain integrity at temperatures as high as 315, which is an ideal choice for industrial furnaces, exhaust systems and solar brackets.

3. high mechanical strength

AZ steel (made of aluzinc steel and galvalume) retains the strength of steel, while gaining the flexibility of coating. It is impact/deformation resistant and can be bent/rolled/stamped without coating cracks. This combination of strength and machinability enables aluminum steel and galvalume to meet structural requirements and reduce the processing costs.

4. Excellent aesthetics and surface performance

Aluzinc steel and galvalume have a smooth, uniform surface needing minimal post-processing. Coils may have chromatic/anti-finger finishes (enhancing corrosion resistance, preventing fingerprints, boosting paint adhesion), making AZ steel ideal for visible uses (facades, appliance exteriors).

5. Cost-Effectiveness

Although the initial cost of aluzinc steel and galvalume steel is slightly higher than that of galvanized steel, their long life and low maintenance cost make their long-term cost lower. Less maintenance/replacement means a higher return on investment for large-scale projects (commercial buildings, infrastructure).

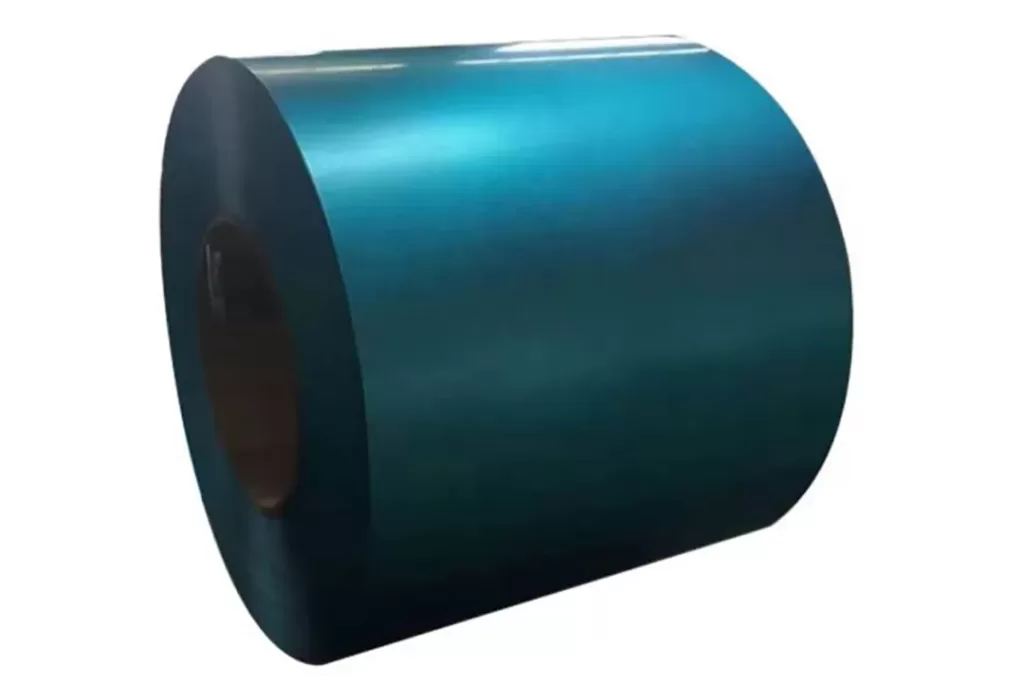

AZ steel product Specifications: Focus on aluzinc steel coil

The most common type of AZ steel is aluminum oxide coils, which meet strict global standards. Important specification:

1. Conform to international standards

Aluzinc steel coils conforms to AISI, ASTM, BS, DIN, GB and JIS standards, ensuring the compatibility in global projects.

2.Range of thickness

0.4-2.5 mm:

· 0.4-1.0 mm: light uses (shell of household appliance, decorative boards).

· 1.0-2.5mm: Heavy-duty applications (roofs, wall, equipment frames).

3. Specifications of the width

900-1500mm: fewer joints are installed (reducing labor costs and improving structural integrity). The width can be customized according to specific requirements.

4. Weight of zinc layer

Corrosion resistance is very important:

· 80-180 g/me: medium environment (inland household and indoor industrial use).

· 30-275g/m: the heavy coating (200-275g/m) of galvalume in harsh areas (coasts and chemical plants) ensures long-term rust prevention.

5. coil weight and inner diameter

· Weight: 3-8 tons (balanced transportation/treatment; Small site 3-5 tons, efficient mass production of 6-8 tons).

· Id: 508/610mm (compatible with most uncoilers).

6. Surface Treatments

· Color: add chromate layer (enhance corrosion resistance/paint adhesion; It is very suitable for painting purposes (such as exterior walls).

· Anti-finger: Prevents fingerprints (great for visible uses like appliance panels).

Main application scenarios of AZ steel (aluzinc steel and Galvalume)

Aluzinc steel and galvalume enable AZ steel to play a role in all walks of life.

1. Building Industry

Top users of AZ steel-take advantage of the durability of aluzinc steel and galvalume.

· Roofing/cladding: aluminum steel coils used for vertical seam roofing (lasting 20-30 years).

· Structural components: purlin, lintels, thick coil of trusses (galvalume handles snow/wind loads).

· Modular buildings: lightweight and easy-to-process aluminum steel accelerates the on-site assembly.

2. Household electrical Appliance Industry

Bauxite steel and galvalume kit.

· Appearance of oven/refrigerator: Galvalume is heat-resistant; Anti-finger aluzinc steel stays clean.

· Washing machine drum: aluminum steel can resist water corrosion.

3. Automobile Industry

Aluzinc steel used for non-structural components.

· Exhaust systems: Galvalume processes high temperature.

· Underboard: Aluzinc steel protects from road salt/moisture.

4. Solar Energy Industry

The corrosion resistance of ——galvalume, a solar bracket made of aluminum oxide steel coil, can make the bracket stand stably outdoors for decades.

5. Agricultural equipment and industrial equipment

· Greenhouses: the aluminum-steel frames can be moisture-proof/moisture-proof.

· Storage tanks: Galvalume plated steel for water/chemical/grain storage tanks.

Conclusion: Why choose AZ steel (aluzinc steel, Galvalume)?

AZ steel (powered by aluzinc steel and galvalume) combines corrosion resistance, heat resistance, strength and value. The detailed specifications (thickness, coating and smoothness) of its aluzinc steel coil are suitable for any purpose, and global standards guarantee quality. For a durable and cost-effective metal solution, AZ steel (together with aluzinc steel and galvalume) is a wise choice for any industry.