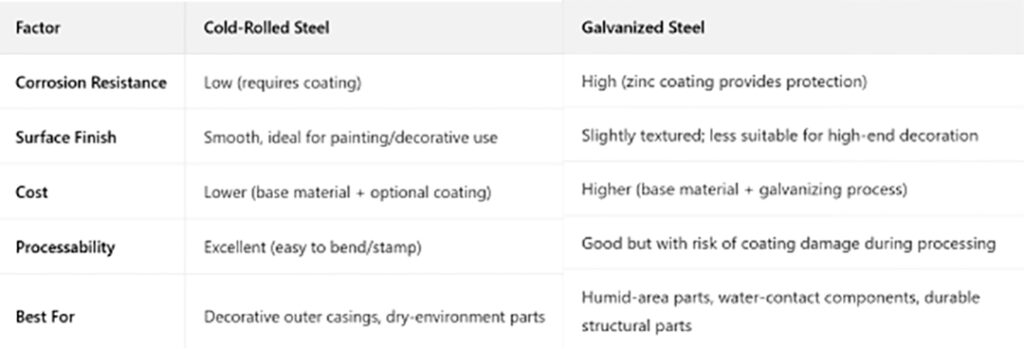

When choosing between cold-rolled steel and galvanized steel for household appliances, their performance, cost, and suitability vary significantly based on core characteristics like corrosion resistance, surface quality, and processability. Below is a detailed comparison of their benefits, drawbacks, and typical applications in household appliances:

Cold-Rolled Steel (CRS)

Cold-rolled steel is produced by rolling hot-rolled steel at room temperature, resulting in a smooth surface, precise dimensions, and higher strength.

Benefits:

Surface Quality: Smoother, more uniform finish (ideal for visible parts like refrigerator panels).

Precision: Tighter tolerances for complex shapes (e.g., oven doors, dishwasher frames).

Paint Adhesion: Better for high-end painted finishes (no zinc layer interference).

Cost-effectiveness: Compared to galvanized steel, cold-rolled steel has a lower base material cost, which helps control the overall production cost of appliances, especially large-volume products.

Drawbacks:

Corrosion Resistance: Requires additional coatings (e.g., powder coating) to prevent rust.

Dependence on secondary coating: To resist rust, it requires post-processing like painting, powder coating, or plastic lamination—adding extra steps and costs. If the coating is scratched or damaged in use, the steel beneath will still corrode.

Typical Uses:

Premium appliances (e.g., stainless-look refrigerators, oven exteriors).

Galvanized Steel (GI)

Galvanized steel is cold-rolled or hot-rolled steel with a zinc coating (applied via hot-dip galvanizing or electro-galvanizing), which provides corrosion resistance through the “sacrificial anode” effect (zinc corrodes first to protect the steel).

Benefits:

Corrosion Resistance: Zinc coating protects against moisture (critical for washing machines, water heaters).

Cost-Effective: Lower upfront cost; minimal post-processing needed.

Durability: Resists scratches/chips better than bare CRS in humid environments.

Drawbacks:

Surface Roughness: Zinc spangles may require extra grinding for smooth painting.

Higher cost: GI price higher than CRS, will increase the overall appliance price—this is a key consideration for budget-friendly products.

Limitations in processing:GI can be stamped or bent, with a thicker zinc layer, it excessive deformation may cause the zinc coating to crack or peel.

Typical Uses:

Structural parts (e.g., washer drums, AC housings), outdoor units.

Summary

Choose cold-rolled steel if the appliance part requires a high-end decorative finish, is used in a dry environment, and can be easily coated (e.g., refrigerator door panels, oven outer casings).

Choose galvanized steel if the part is exposed to moisture, water, or humidity (e.g., washing machine drums, water heater tanks) and prioritizes durability over a ultra-smooth appearance.

In practice, some appliances combine both: for example, a washing machine may use cold-rolled steel for its outer decorative panel (painted for aesthetics) and galvanized steel for its inner drum (for rust resistance).