In the demanding world of heavy industry, machines are faced with ruthless impact, crushing pressure and wear, and standard materials often fail to meet the requirements. Enter High Manganese Steel Plate–a remarkable alloy engineered specifically to thrive under the harshest conditions. Known for its unparalleled ability to absorb massive impacts while simultaneously developing extreme surface hardness, this material is the cornerstone of longevity in critical applications. But what is it that makes it so special? Let us deeply understand the scientific, manufacturing and practical advantages of this extraordinary steel.

Understanding high manganese steel: the science of work hardening

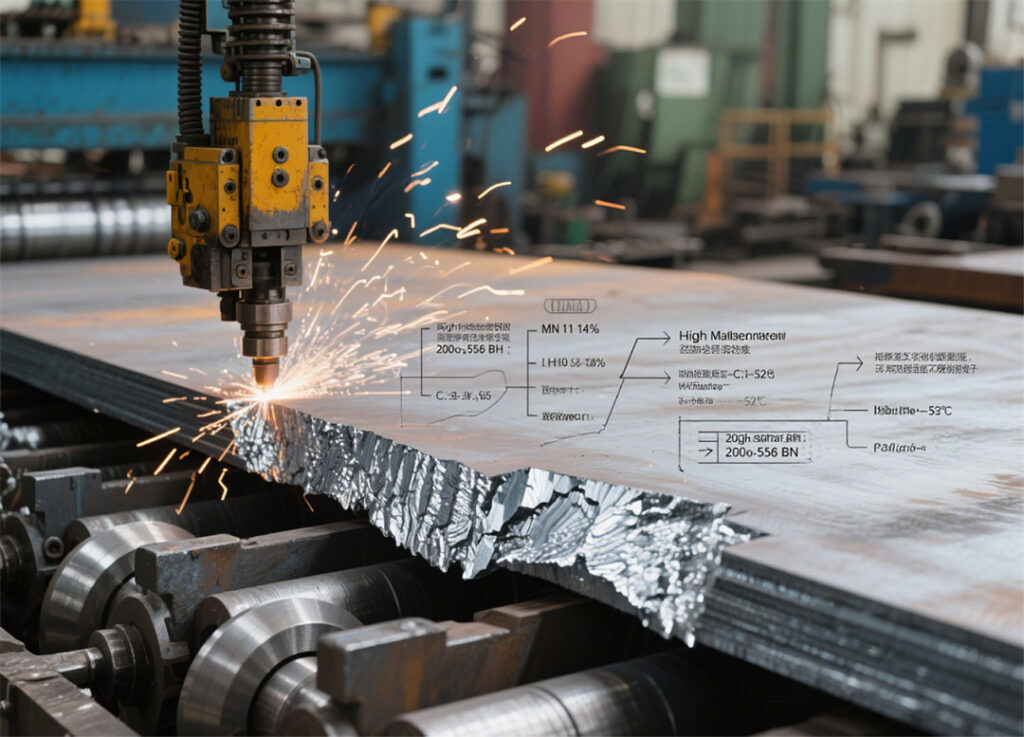

The core of high manganese steel (usually named as hadfield steel after its inventor Sir Robert hadfield) is an austenitic alloy, which is characterized by extremely high manganese content (usually wMn = 11% -14%) and high carbon content (wC = 0.9% -1.45%). Unlike most steels whose hardness is mainly obtained through heat treatment, the legendary wear resistance of high manganese steel comes from a unique phenomenon: work hardening.

· Initial state: In its initial, solution-annealed state, the steel possesses a relatively modest hardness (around HB 200) and a highly ductile, tough austenitic microstructure.

· Deformation under Impact: when the surface is subjected to great impact, pressure or strong wear, miracles will happen. This mechanical energy results in deformation in austenite lattice.

· Surface hardening: This deformation will cause rapid transformation at the surface layer, transform soft austenite into incredibly hard martensite, or inducing severe strain hardening. The surface hardness can soar from HB 200 to more than HB 500 (550 BHN).

· Self-Renewing Armor: As this hardened surface layer wears away through service, the underlying material is exposed to the impacting forces, causing it to work harden in turn. This creates a continuously renewing, ultra-hard wear surface.

· Tough core: It is very important that although the surface hardens sharply, the underlying core still maintains its original tough and tough austenite structure. This provides exceptional resistance to crack propagation and catastrophic failure under shock loading–a critical advantage over brittle, through-hardened materials.

Unparalleled advantages of high manganese steel plate.

The unique work strengthening mechanism is transformed into a series of remarkable advantages:

1. Superior Impact & Abrasion Resistance: the best choice for components subjected to severe impact combined with high-stress abrasion. Under these conditions, the performance exceeds that of many other wear-resistant materials.

2. Dynamic Hardening: the surface work hardens rapidly (up to 550 BHN) in direct response to the level of impact or pressure applied. The greater the impact, the harder its surface will become.

3. It boasts excellent toughness and ductility. Even when the surface is hardened, it can maintain high impact toughness (the test temperature is as low as -52°C) and the ductility of the whole core. This prevents brittle fracture under impact loads.

4. Weldability: High Manganese Steel Plate is distinct from certain ultra-hard materials in that it can be welded using the right procedures and consumables. This makes it useful for fabrication and repair.

5. Machinability (when using suitable tools): Although it is difficult to process using conventional methods, it can be effectively cut using thermal methods.

· Oxy-acetylene torch

· Plasma cutting process

· Water jet cutting process

· Laser Cutting Technology

6. Non-Magnetic Properties: The retained austenitic structure makes it non-magnetic, which is essential for certain applications, such as mining equipment near magnetic separation systems or sensitive electronics.

7. Long service life: It is designed and manufactured according to the most stringent international standards. These standards include AISI, ASTM, BS, DIN, GB, and JIS. The goal is to ensure a long service life. This also reduces downtime and replacement costs in harsh environments.

Specification and properties of Runfei high manganese steel plate.

As a leading manufacturer following the global standards, Runfei Iron and Steel Group (Tianjin, China) provides high-quality rolled high-manganese steel plates with the following specifications.

· Product Name: High manganese steel plate (e.g. Manganese 13)

· Thickness Range: 35 mm to 150 mm.

· Width Range: 1000 mm to 4500 mm.

· Length Range: 3000mm-18000mm (the length can be customized.

· Standards met: AISI, ASTM, BS, DIN, GB and JIS.

· Key performance: impact test at-52 degrees Celsius to ensure low-temperature toughness.

· Customization: The Grades and specifications can be tailored to meet the requirements of specific customer.

Diverse Applications: Where High Manganese Steel Plate Excels

The unique combination of extreme abrasion resistance and core toughness under impact makes this material indispensable in many heavy industries.

Mining and quarrying: Crusher liners, hammer head, buckets, buckets, sieve plates and feeding tray-absorb the impacts of large rock.

Cement Production: crusher hammers head, impact plates, crusher roller and liners, clinker crusher parts-wear-resistant clinker and raw materials.

Recycling & Scrap Handling: Shredder hammers, anvils, liners, grapple tips–enduring impacts from fragmented metal.

Railway: frog tip, crossing nose and turnout parts-dealing with the impact and wear of train wheels.

Construction and demolition: bucket teeth and lips of excavators, jaws plates of crushers for concrete recycling-dealing with abrasive demolition debris and rock.

Shot blasting: the pads and parts in the shot blasting machine-constantly bombarded by abrasive.

Power Generation: coal pulverizer rolls and rings, ash handling systems–resisting abrasive coal and ash.

Shipbuilding and dredging: cutter heads, suction nozzle and bucket parts of dredger-bearing underwater impacts and wear.

Ball Mills & SAG Mills: Lifter bars, feed heads–subjected to impact from grinding media and ore.

Runfei Steel Group: your partner of wear-resistant solutions

Established in 1998 and headquartered in the major port city of Tianjin, China, Runfei Steel Group has grown into a large-scale enterprise renowned for its expertise in steel production and distribution. Leveraging Tianjin’s logistical advantages and a robust network for storage, processing, and distribution, Runfei is committed to providing high-quality products like their High Manganese Steel Plate backed by reliable service and a strong reputation.

Frequently asked questions: high manganese steel plate.

Q1. What payment terms do you accept?

A: We accept T/T (Telegraphic Transfer) and L/C (Letter of Credit).

Q2. What grades can you offer?

A: We primarily offer Mn13 grade rolled plate. Products can also be customized according to your specific technical requirements.

Q3. Are free samples available?

A: Yes, free samples are available for evaluation. Contact us to discuss your needs.

Experience the Runfei Difference

If your operations is faced with relentless challenge of impact and wear, Runfei’s high manganese steel plate provides an effective solution. Its unique work-hardening properties provide unparalleled life and cost-effectiveness in the worst environment in the world.

Ready to improve the durability of the equipment and reduce downtime?

Contact us directly on WhatsApp:+86 176 9494 2340.

Fill in the following feedback form, and our team will contact you in time to discuss your specific requirements for high manganese steel plates.