1. Where Does the Heat Come From? How PV Brackets Become “Heat Bridges”

Photovoltaic (PV) systems are constantly battling high temperatures. Under intense sunlight, the surface temperature of solar panels can easily reach65–75°C, significantly exceeding their standard operating temperature.

This high temperature doesn’t just affect the panel itself (reducing power output); it is also transferred through physical contact to the metal mounting brackets and rails beneath. These metal brackets act as highly efficient “heat bridges,” transferring heat directly to the wires and clips fastened to them. As a result, the electrical wires must withstand a localized heat load much higher than the surrounding air, making this the primary factor influencing the wire’s lifespan.

2. Why Is High Temperature Harmful to Wires?

The harm caused by high temperatures to PV wires primarily falls into two categories: reduced system efficiency and shortened wire lifespan.

2.1. Reduced Generating Efficiency (Increased Resistance)

When wires transmit current, electrical resistance naturally generates heat. As the ambient temperature (from the brackets and roof) rises, the resistance in the wire’s conductor also increases. This increased resistance leads to greater energy loss (voltage drop), which ultimately reduces power output and lowers the overall system efficiency.

2.2. Accelerated Wire Aging and Safety Risks

Cable insulation (typically plastic material) is designed with a maximum safe operating temperature (standard PV cables are generally rated for 90°C). If the cable is exposed to temperatures exceeding this limit for prolonged periods, the insulating material will accelerate its aging process, become brittle, and eventually break down .

In the PV industry, when cables are exposed to high-temperature environments, their safe current-carrying capacity must be derated (reduced) . If installers ignore this requirement, the cables will operate in a chronically overloaded state. This not only increases the risk of fire but can also cause connectors to deform or melt .

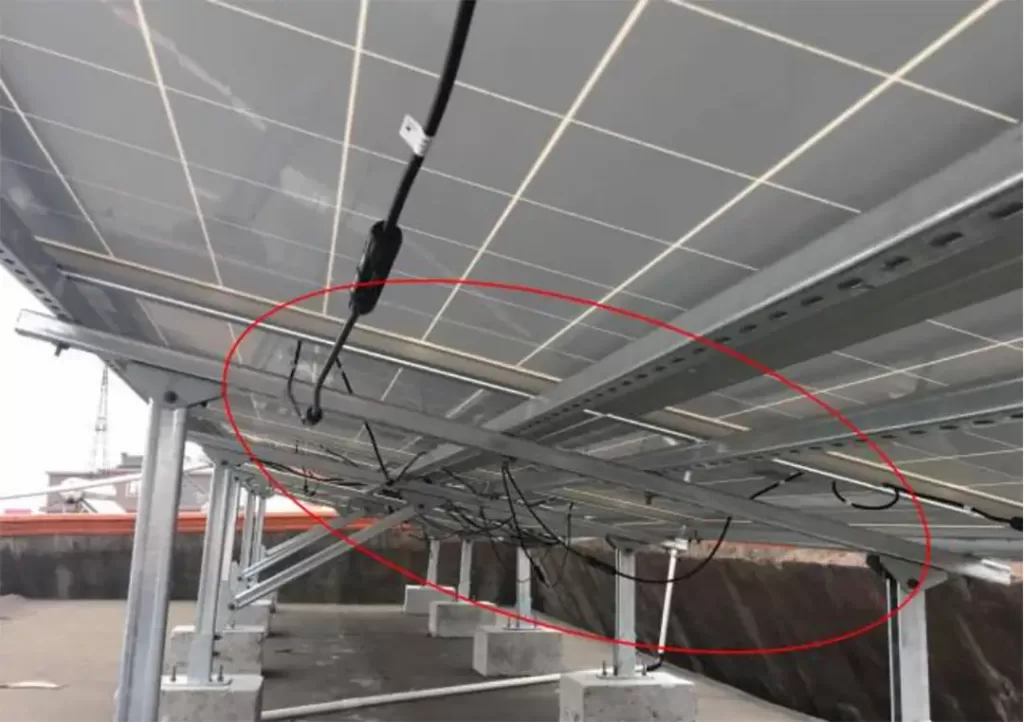

2.3. Mechanical Damage Risk

The metal brackets undergo significant thermal expansion and contraction due to temperature fluctuations between day and night. This repeated movement puts stress on the cable ties or clips used for fastening. If the fasteners (like standard nylon zip ties) lack sufficient heat and UV resistance, they will quickly become brittle and break. Once a fastener fails, the cable may loosen and potentially rub against the sharp edges of the hot metal rail, damaging the insulation and causing a short circuit.

3. How to Ensure Wire Durability? Three Installation Strategies

Professional installation practices and the correct choice of materials are crucial for guaranteeing the long-term durability of PV wiring.

| Key Strategy | Purpose | Practice Points |

| Maintain Air Gaps for Cooling | To reduce the temperature of the brackets and cables at the source. | Ensure adequate space (e.g., 100 mm air gap) between the bottom of the solar panel and the roof to allow for natural convection cooling. |

| Select Professional-Grade Materials | To ensure all components can withstand the extreme environment. | Wires: Must use professional wires (such as XLPE), which feature excellent UVand high-temperature resistance. Fasteners: Choose high-specification, heat-stabilized nylon or stainless steel ties/clips, rated for sustained temperatures of $125°C or higher, with superior UV resistance. |

| Optimize Wiring Path | To avoid direct contact with heat sources and mechanical abrasion. | Avoid Contact: Wires must be kept clear of hot roof surfaces or any sharp metal edges. Maintain Clearance: Avoid routing wires near other heat sources (like chimneys, vents, or HVAC equipment), maintaining a minimum clearance of 3 feet (approx. 91.4cm . Allow Slack: Use “Service Loops” in the wiring—appropriate slack—to absorb the movement caused by the thermal expansion and contraction of the mounting structure, preventing the wires from being stressed or pulled. |

By implementing these best practices for thermal management and installation, you can minimize the negative impact of bracket heat on wire durability, ensuring the stable, safe, and long-term operation of your PV system.

Picture source:

1. https://www.1688.com/zw

2.http://fjlwj.csggjx.com/