When you admire the flawless finish of a car or touch the smooth casing of a high-end refrigerator, you might not realize that the unsung hero behind it is a special material: electro-galvanized (EG) steel. It’s not just a guardian against rust; it’s the key to achieving aesthetic perfection in modern manufacturing.

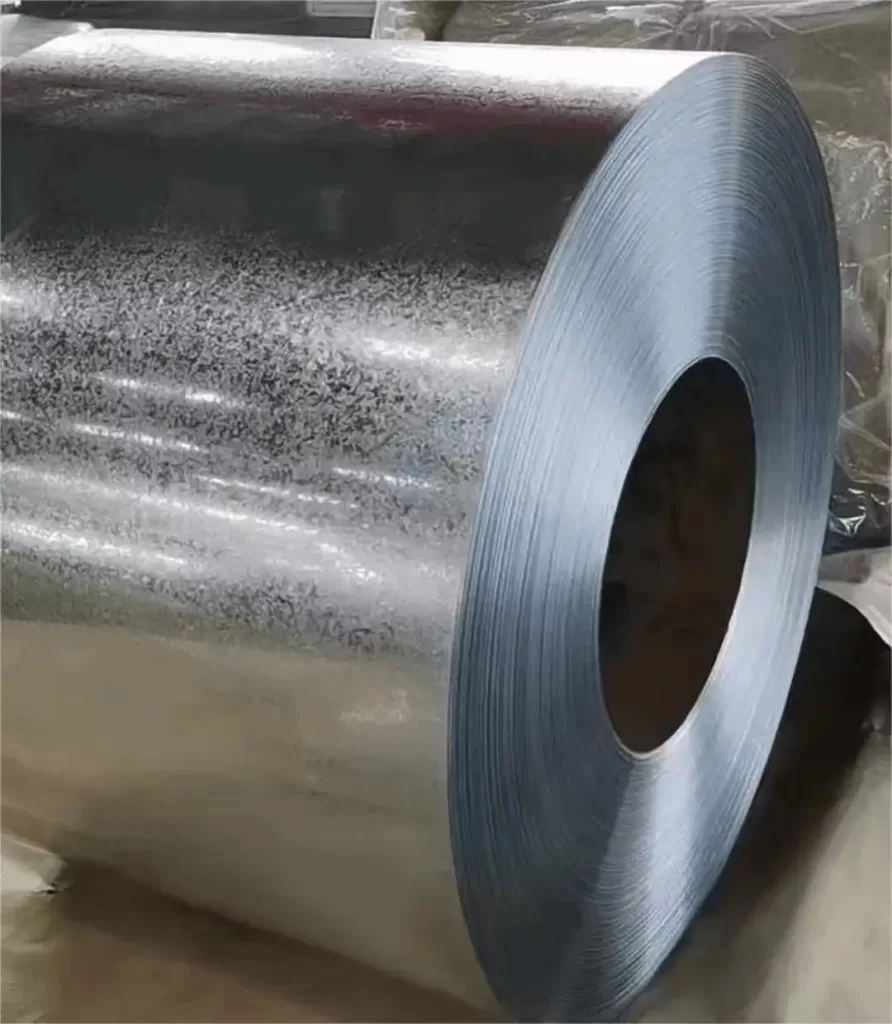

What is Electro-Galvanized Steel?

Simply put, electro-galvanized steel is created by applying a thin, dense layer of pure zinc to a cold-rolled steel sheet through electrolysis. Unlike hot-dip galvanizing, which involves immersing steel in molten zinc at high temperatures, electro-galvanizing is a “cold” process performed at room temperature, akin to a precise electrochemical “surgery”.

This process gives it a distinct core advantage: an extremely smooth surface with a uniform thickness.

Why Does High-End Manufacturing Prefer It?

Choosing electro-galvanized steel signifies a commitment to detail and quality.

Superior Aesthetics: It boasts an “A-class” smooth surface, free of spangles or patterns, making it the ideal base for the perfect paint finish on cars and the premium texture of home appliances.

Excellent Formability: The thin, flexible zinc layer allows the steel to be stamped and bent into complex shapes without the coating cracking or peeling, giving designers immense creative freedom.1

Perfect Paint ability: Its smooth surface allows paint to adhere firmly, making it easy to achieve a flawless, high-gloss finish.

Reliable Protection: The zinc layer is not just a physical barrier. If the coating is scratched, its “sacrifices” itself by corroding first to protect the steel underneath, offering dual-layer protection.

Where Does It Shine?

Electro-galvanized steel is predominantly used in applications where appearance is paramount.

1. Automotive Industry

From doors and hoods to trunk lids, the “A-class” exterior panels that define a car’s visual quality are almost exclusively made from electro-galvanized steel to achieve that stunning, mirror-like paint finish.

2. Home Appliances

The casings of high-end refrigerators, washing machines, and air conditioners rely on electro-galvanized steel to create their modern, clean, and high-quality appearance. Functional additions like anti-fingerprint coatings further enhance the user experience.

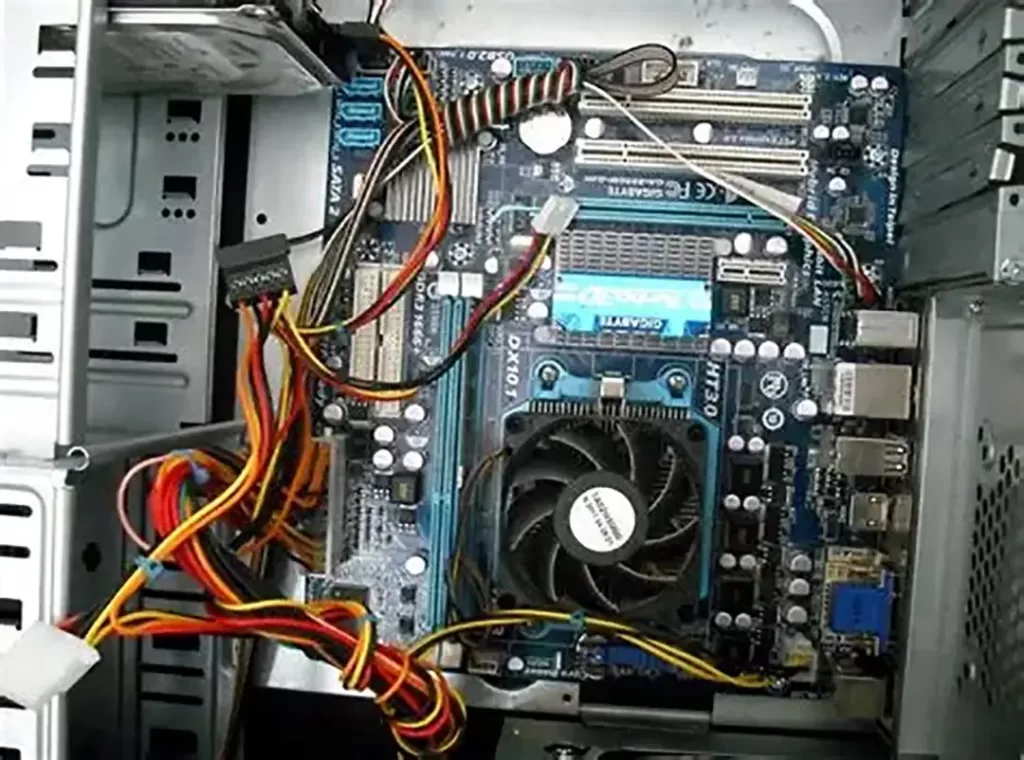

3. Electronics & Office Equipment

Computer cases, server cabinets, and metal file cabinets also make extensive use of electro-galvanized steel. It provides the perfect balance of strength to protect sensitive components, a professional look, and cost-effectiveness, serving as the sturdy armor for our digital world.

4. Interior Architecture

Indoors, electro-galvanized steel is favored for high-end metal door frames, interior partitions, and shelves due to its ease of painting and ability to blend seamlessly with interior designs.

Conclusion

Electro-galvanized steel is far more than just a rust-proof material. It is a strategic choice—an investment in product aesthetics, user experience, and brand value. The next time you are captivated by a product’s exquisite exterior, remember that electro-galvanized steel might just be the secret behind its appeal.

Images source

Image1:Taobao.com

Image2:699pic.com

Image3:Re1688.com

Image4:B2b.baidu.com

Image5:Bbs.zhulong.com