1. Overview: The Outstanding Performance of ZAM Alloy in Extreme Environments

For high-altitude photovoltaic (PV) power stations, solar brackets must withstand the dual challenges of strong winds and humid environments. ZAM (Zinc-Aluminum-Magnesium) alloy coated steel is a cutting-edge material designed precisely for this purpose. With its unique alloy composition, it achieves a perfect balance between cost-effectiveness and superior performance, surpassing traditional Hot-Dip Galvanized (HDG) steel and aluminum alloys.2 ZAM brackets not only possess great structural strength but also offer unparalleled corrosion resistance and a unique self-healing function, making them the ideal choice for ensuring the long-term stability and success of high-altitude PV systems.

2. Core Advantages: Corrosion Resistance, Self-Healing, and Structural Strength

The superiority of ZAM alloy stems from its distinctive material properties. The coating is a proprietary alloy of zinc, 6% aluminum, and 3% magnesium. When exposed to a humid environment, this coating forms a dense, stable protective film that effectively blocks corrosive elements.2 Laboratory tests show that ZAM’s corrosion resistance is 5 to 10 times higher than that of traditional HDG steel, performing exceptionally well in humid and chemically corrosive environments.7 This remarkable anti-corrosion capability ensures that ZAM brackets can maintain their performance over the long term, even in severe coastal or high-humidity environments, with a designed lifespan of 25 to 30 years.7

Another key advantage of ZAM is its unique “self-healing” function. On-site cutting and drilling are unavoidable during the installation of mountain projects, which exposes the inner steel to the risk of corrosion. The zinc and magnesium components in the ZAM coating migrate to these exposed edges, forming a stable protective film upon contact with moisture. This spontaneous process requires no manual intervention, fundamentally solving the problem of “red rust” that is common at the cut edges of traditional HDG steel, and greatly ensuring the long-term integrity of the entire bracket system.

Furthermore, ZAM brackets provide superior structural strength due to their steel substrate. In high-altitude areas, brackets must be able to withstand significant wind loads and gusts. Compared to aluminum alloys, which require more material to achieve the same strength, the steel core of ZAM brackets can easily handle these challenges, ensuring the stability of the PV array even under the harshest weather conditions.

3. Return on Investment and Sustainability

While the initial cost of ZAM brackets is slightly higher than that of traditional galvanized steel due to their advanced coating process, it represents a wiser investment when considering the total cost of ownership over a project’s life cycle. ZAM’s exceptional corrosion resistance and long lifespan (up to 25-30 years) mean that minimal maintenance and repair are required throughout the project’s life. This significantly reduces operational costs and ensures a stable, long-term return on investment.

Additionally, choosing ZAM aligns with the principles of sustainable development.11 Its production process is more environmentally friendly than traditional hot-dip galvanizing, generating fewer harmful emissions and waste. The thinner coating provides stronger protection, reducing zinc usage and environmental runoff. Its excellent durability also reduces the need for replacements, thereby decreasing resource consumption and environmental impact.

4. Conclusion and Recommendation

For high-altitude PV projects facing the extreme challenges of wind and rain, ZAM zinc-aluminum-magnesium alloy coated steel brackets are an excellent solution to all challenges. Their unparalleled corrosion resistance, crucial self-healing capability, and strong structural integrity collectively ensure the long-term reliability of the photovoltaic system in a severe environment. Despite a slightly higher initial investment, the long-term cost savings and higher return on investment they provide make them a smart decision that achieves a perfect balance between performance, cost, and sustainability.

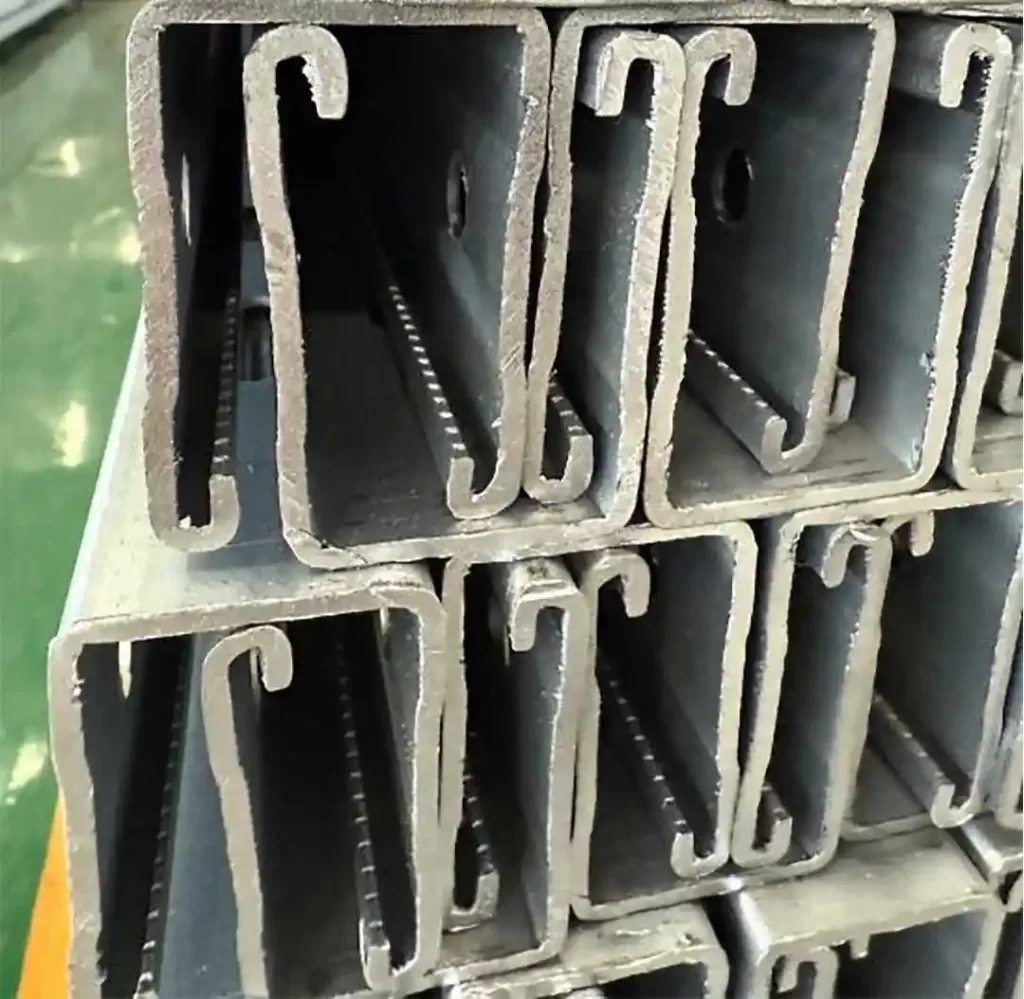

Photo source

Photo by Jeff, Tianjin Runfei Trading Co., Ltd.