Part 1: The definition and historical origin of zinc, aluminum and magnesium

Definition: Zinc, aluminum and magnesium is an alloy metal, mainly used for surface anti-corrosion treatment of steel and steel products, including various zinc series coatings and a large number of whole steel parts immersion anti-corrosion; initially used as steel The metal used for the surface anticorrosion treatment of the product is pure zinc. With the improvement of technology, alloy metals such as aluminum-zinc alloy and zinc-aluminum-magnesium alloy have appeared one after another, which increases the corrosion resistance of the metal layer.

Origin: It was originally developed and mass-produced by Japan’s Nisshin Steel Corporation in the early 21st century. It is said that the purpose of development is to replace certain stainless steel applications. Domestic steel mills currently have production in Jiuquan Iron and Steel, Tangshan Iron and Steel and Baosteel. As the industry upgrades, this will be a widely used material.

Part 2: Composition and classification of zinc, aluminum and magnesium

Zinc-aluminum-magnesium coated steel sheet refers to a coated steel sheet in which a certain amount of Al, Mg is added to the existing hot-dip galvanized coating or a certain amount of Mg is added to the hot-dip galvanized coating. It has high corrosion resistance and high Features of trimming protection performance.

For commercial application of magnesium-containing coated steel sheets, the magnesium content of most coatings is ≤3%. According to the aluminum content of the coatings, the zinc-aluminum-magnesium coatings are divided into:

1. Low-aluminum-zinc-aluminum-magnesium coating, aluminum content: 1-3.5%, the coating is formed by adding a certain amount of aluminum-magnesium and other elements on the basis of hot-dip galvanizing. The coated steel plate has also been tested in a color coating unit and successfully developed A low-aluminum-zinc-aluminum-magnesium substrate color coated steel sheet.

2. Medium aluminum zinc aluminum magnesium coating, aluminum content: 5~11%

3. High-aluminum-zinc-aluminum-magnesium coating, aluminum content: 55%, the coating is formed by adding certain magnesium and other elements on the basis of hot-dip aluminum-zinc. The coated steel plate has also been tested in color coating units and successfully developed. Color coated steel plate with aluminum-zinc-aluminum-magnesium substrate.

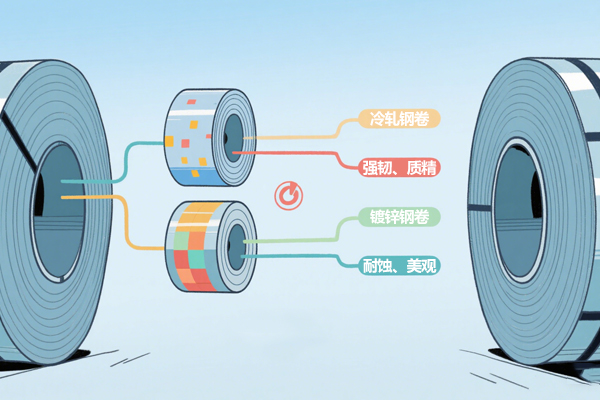

Part 3: Comparison between pure zinc, aluminum zinc and zinc aluminum magnesium

1. Pure zinc coating, a metal coating with a zinc content of not less than 99%, is an economical anti-corrosion coating; it is divided into galvanized steel and zinc-free galvanized steel, the corrosion resistance of the two is almost the same. If spraying or painting is required in the follow-up, the products without spangles will be more beautiful; while the thick zinc layer products usually have flowers (for example, the weight of the zinc layer is 275g/m2 on both sides).

2. Aluminum-zinc coating is an alloy metal, in which the aluminum content is 55%, the zinc content is 43.5%, and the remaining component is silicon. Generally, the corrosion resistance of the aluminum-zinc coating is 2-6 times that of the same weight of pure zinc coating . The surface of galvanized steel coil can be modified by production technology to produce beautiful and uniform spangles, which can be directly used for building exterior or household appliances. However, there are some disadvantages of galvanizing. First, the welding performance of galvanizing is not as good as that of pure zinc. The welding process should be reduced as much as possible during use; second, the cut protection of galvanizing on steel plate is much lower than that of pure zinc. Far inferior to zinc-aluminum-magnesium coating.

3. The zinc-aluminum-magnesium coating is an alloy metal with excellent comprehensive performance. The manufacturing cost is only slightly higher than that of the aluminum-zinc coating. The corrosion resistance of the coating is much higher than that of pure zinc and aluminum-zinc alloy, and it also protects the cut of the steel plate. The performance is very good, and the welding performance is equivalent to that of pure zinc steel. At present, there have been cases of direct application of zinc-aluminum-magnesium steel sheets on the market. At the same time, the zinc-aluminum-magnesium color-coated sheets used as color substrates have also been mass-produced and applied in large quantities by Baosteel. The directly bare zinc-aluminum-magnesium steel sheets are high-aluminum-zinc Aluminum-magnesium, zinc-aluminum-magnesium steel sheet as a color substrate belongs to low-aluminum-zinc-aluminum-magnesium. In the future, as the requirements for materials in construction and various industries gradually increase, zinc-aluminum-magnesium coated steel sheets may gradually replace the application of aluminum-zinc steel sheets in the market.