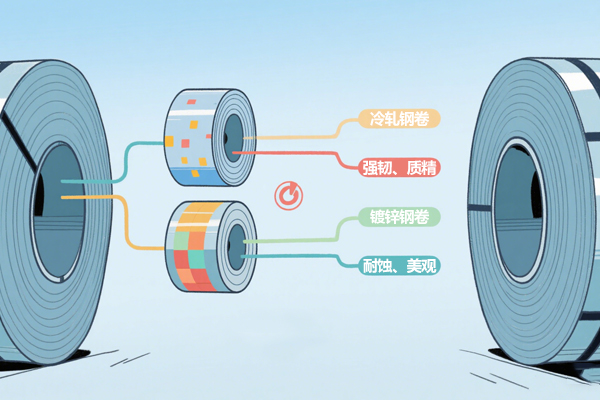

PPGL is the abbreviation of Pre-painted galvalume typically with a hot dip Al-zinc coated steel substrate. It is made from the base metal cold rolled steel coil then undergone the process of coating an alloy of aluminium and zinc with the usual rate of 55% Al, 43.5% Zn,1.5% Si and painted with various painting types according to customers’ tastes.

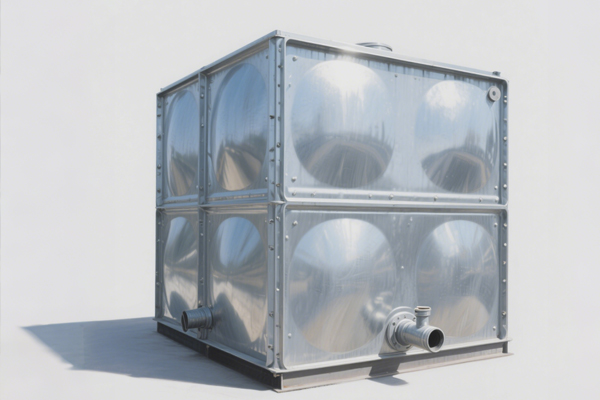

Rely on its excellence performance, pre-painted galvalume steel coil has been widely applied in building, sandwich panels, metal roofing, light industry, and other areas. As the fact that its different applications in many environment conditions, the choice of appropriate PPGL should be paid special attention. Here are some advantages that are outweigh other steel types:

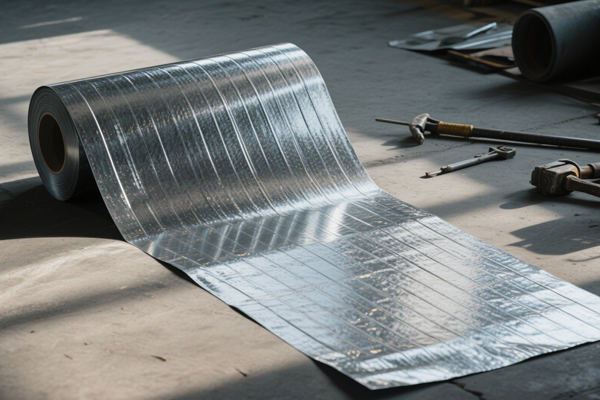

Thanks to the alloy of Al and Zn, PPGL is highly resistant to the corrosion and environmental damage. Especially, in nearby sea environment, the corrosion resistance rate is much more higher than PPGI.

The Al composition creates a mechanical barrier against environmental impacts and cures scratches on steel sheet surface. While the Zn composition protects the sacrificial electrochemical by automatically creating a protective compound for the base steel layer at the cutting edges. Combining with other chemical treatments and paint layers, anti-oxidation and anti-corrosion ability of PPGL is improved significantly.

Especially, the alloy of Al and Zn does not only help corrugated roofing sheet to increase anti-oxidant capacity and durability, but also to reflect lighting effect and limit the absorption of heat energy from the sun.

Nowadays, there are many substandard PPGL which affects the basic traits and the durability of steel sheet. With that concern, MRS STEEL really hopes to bring pre-painted galvalume with good quality to the market. We do suggest PPGL from Vietnam with quality is recognized by many marktes around the world.