1. Definition

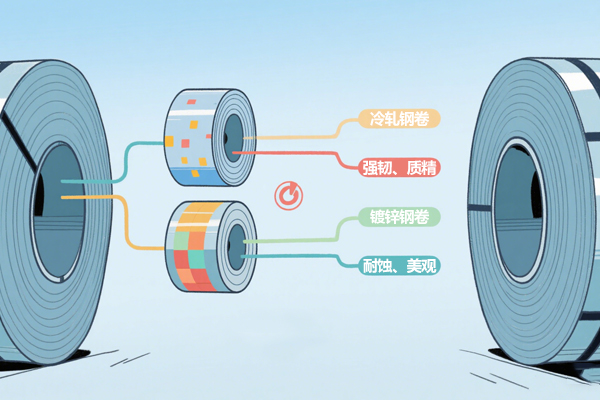

1. Galvalume:

The hot-dip galvanized steel sheet is a cold-rolled steel sheet as the base material, and the coated steel sheet is obtained by hot-dip aluminum-zinc alloy coating on both sides. The mass percentage of the alloy composition of the coating is 55% Al, 43.5% Zn and 1.5% Si.

2. Galvanized aluminum magnesium:

In the hot-dip galvanizing production line, the pre-treated steel strip is immersed in the molten zinc solution containing aluminum and magnesium to obtain the coating.

The alloy coating composition has the following proportions:

①The magnesium content is 1.0~2.0%, and the aluminum content is 0.8~3.0%

②The magnesium content is 3%, and the aluminum content is 11%

2. Product features

1. Galvalume

Hot-dip 100-200g/m2 of 55% AlZn protective layer on the steel substrate. The corrosion resistance is mainly due to the protective function of aluminum and aluminum. When zinc is worn, aluminum forms a dense layer of aluminum oxide, which prevents corrosion-resistant substances from further corroding the interior. The alkali corrosion resistance is weak; the protection period is 8-15 years.

2. Galvanized aluminum magnesium

The main ingredient is 3%Mg-11%Al-Zn, which has strong chlorine resistance (salt/sweat/salt/sea breeze/soil) and alkali corrosion resistance, self-repairing function, and can guarantee no redness for 20-30 years rust.

Third, the characteristics of galvanized aluminum magnesium products

1. Al, Mg, Si and other alloy elements are added to the coating of hot-dip galvanized aluminum-magnesium steel, which greatly improves the corrosion inhibition effect of the coating. Compared with ordinary galvanized products, the coating has less adhesion but can achieve better corrosion resistance. , It is 10-20 times of hot-dip galvanized steel sheet.

2. The coating composition around the cutting surface continuously dissolves to form a dense protective film mainly composed of zinc hydroxide, alkaline zinc chloride and magnesium hydroxide. This protective film has low conductivity and inhibits the corrosion of the cut surface. effect.

3. Because the super corrosion resistance is 10-20 times that of ordinary hot-dip galvanized sheet and the corrosion-resistant self-healing effect of the cut section, the service life of components made of hot-dip galvanized aluminum-magnesium steel alloy coated sheet will naturally be very long. , Under normal circumstances, it can reach more than 30 years.