Prepainted Galvanized Color-coated Coils (PPGI)is an important metal material widely used in the fields of construction, home appliances, automobiles, etc. Its surface has the characteristics of beauty, durability, corrosion resistance, etc., so it is highly favored in the market. This article will provide a detailed introduction to PPGI, including their manufacturing process, performance characteristics, application areas, and market prospects.

1, Manufacturing process

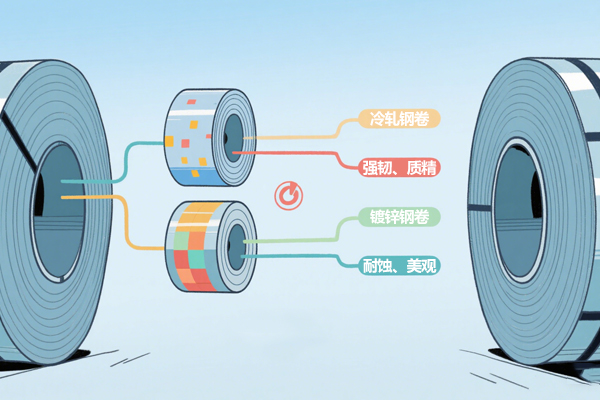

PPGI are formed from hot-dip galvanized steel plates as the substrate after surface coating treatment. The manufacturing process mainly includes the following steps:

Hot dip galvanizing: After degreasing, cleaning, melting and other treatments, the steel plate is hot-dip galvanized in a zinc pot to form a layer of zinc to improve the corrosion resistance of the steel plate.

Surface coating: Apply various coatings on the surface of the zinc layer to form a beautiful, durable, and corrosion-resistant coating. The painting process can adopt methods such as spraying, roller coating, electrophoresis, etc.

Curing: The coating undergoes high-temperature curing treatment to form a strong coating film.

2, Performance characteristics

PPGI have the following performance characteristics:

Corrosion resistance: Due to the presence of galvanized layer, color coated coils have good corrosion resistance and can be used for a long time in different environments.

Aesthetics: The coating can form various colors and patterns, giving the colored coating roll a beautiful appearance.

Durable: The coating has high hardness and wear resistance, and is not easily scratched or worn.

Environmental protection: The manufacturing process of PPGI does not use any harmful substances and meets environmental protection requirements.

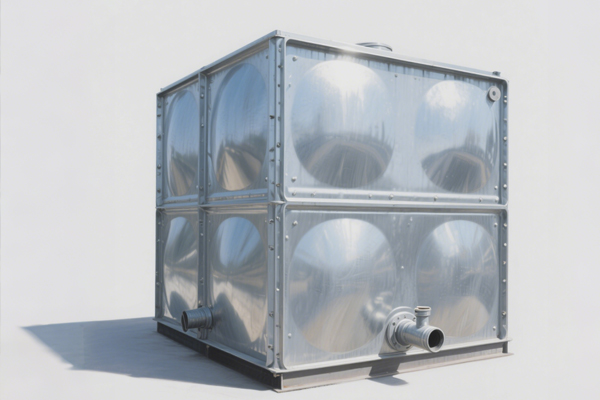

3, Application field

PPGI are widely used in fields such as construction, home appliances, and automobiles. In the field of architecture, color coated rolls are mainly used for the manufacturing of roofs, walls, doors and windows, and other parts; In the field of household appliances, color coated rolls are mainly used for manufacturing the outer shell and internal parts of household appliances such as washing machines, refrigerators, and air conditioners; In the automotive industry, color coated rolls are mainly used for the manufacturing of parts such as car bodies and doors.

4, Market Outlook

With the continuous development of technology, the performance and quality of galvanized color coated coils are also constantly improving, and their application fields are also expanding. In the future, with the improvement of environmental awareness and the requirements of sustainable development, the market prospects of galvanized color coated coils will be even broader. Meanwhile, with the continuous emergence and application of new materials, PPGI also require continuous technological upgrades and innovations to meet market demands.